Full Mission Engine Room Simulator (ERS)

by GDS Engineering R&D

(Ship Engine Room Simulator, SERS™)

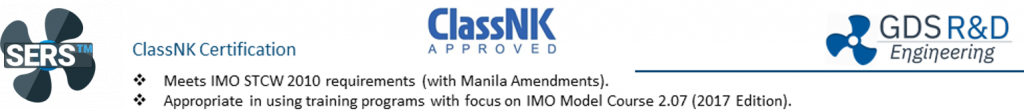

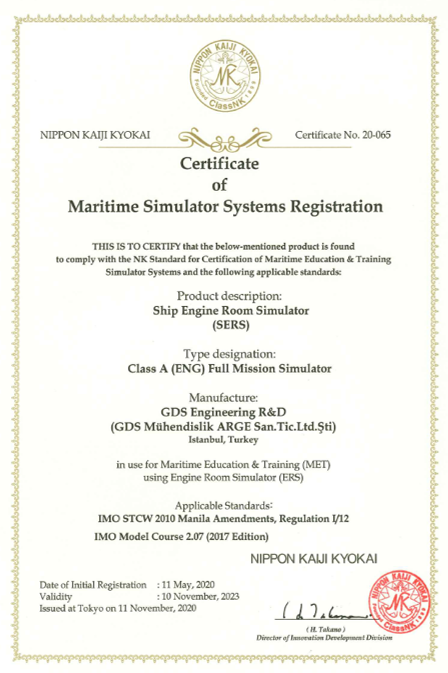

Certified by ClassNK

Meets both IMO STCW 2010 and IMO Model Course 2.07 training and exercise requirements

GDS Ship Engine Room Simulator (SERS™) is an advanced FULL MISSION engine room simulator. In order to understand how it is advanced, please read through the list of the items provided in below sections. Please do not hesitate to communicate with us with your “how….?” and “why…?” questions. We are here to help you achieve your training objectives.

Highlights of the GDS Engine Room Simulator (Ship ERS or SERS™)

- Certified for use in training and education of marine engineering cadets.

- Certified by ClassNK, a Japanese Classification Society. Class NK is an official member of IACS.

- Certification includes IMO STCW 2010 (with Manila Amendments)

- Certification type is Full Mission (Class A) type approval.

- Certification includes IMO Model Course 2.07 (2017 Edition).

- Applicable for Remote (Online) Training

- Provides two types of mostly used engine modes.

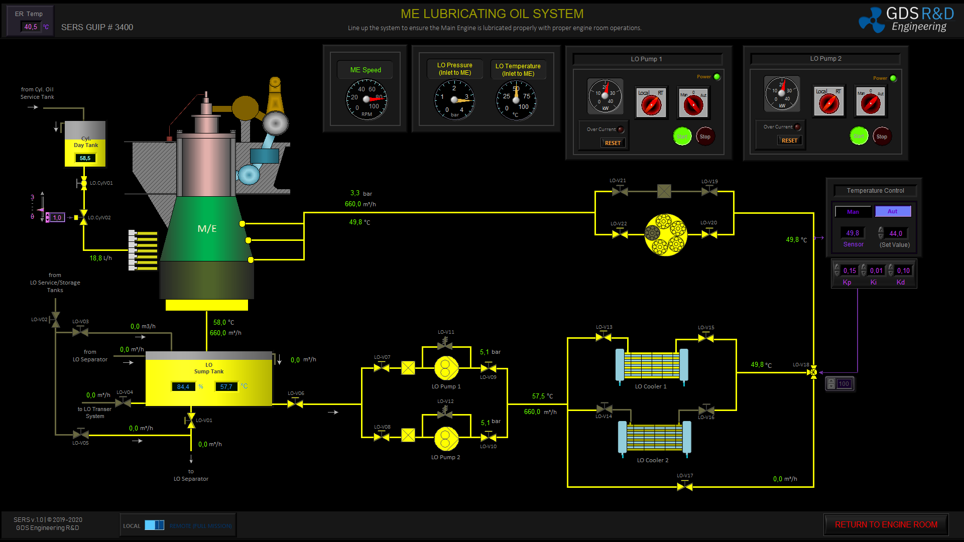

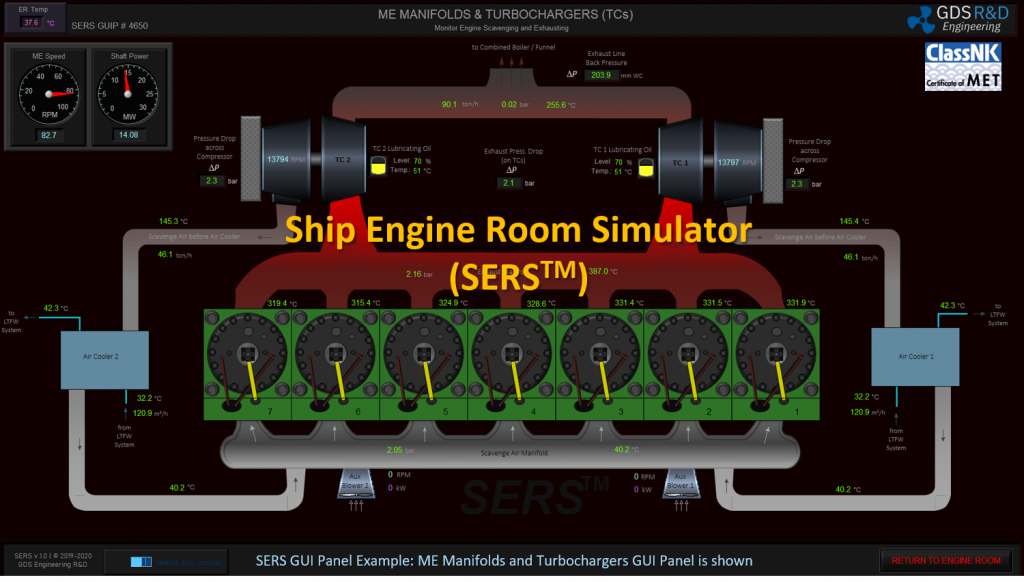

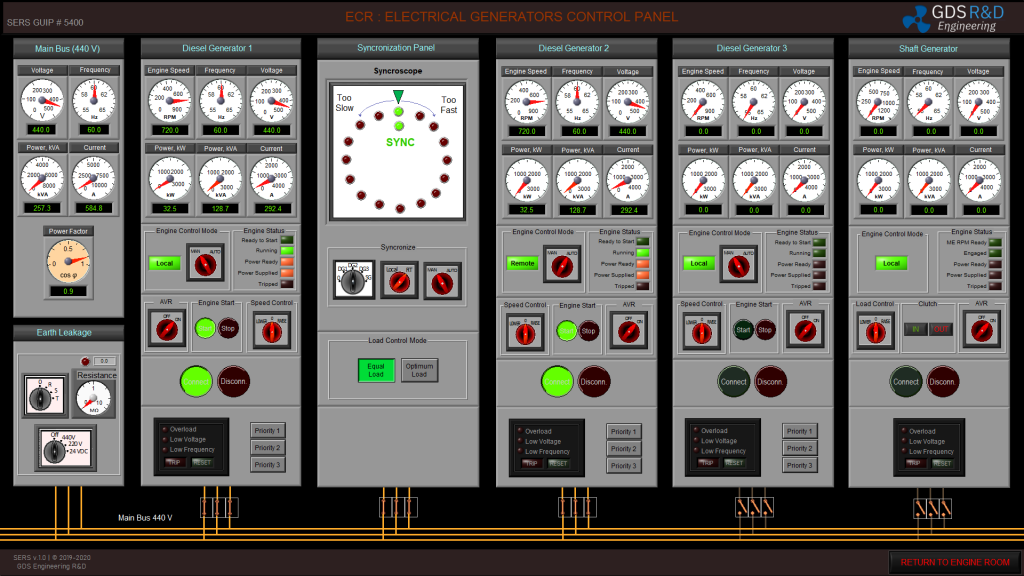

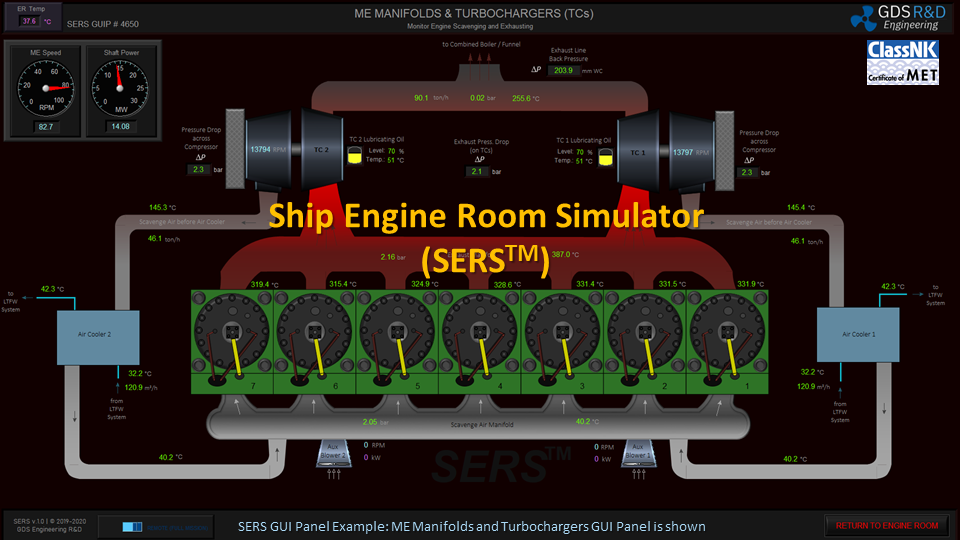

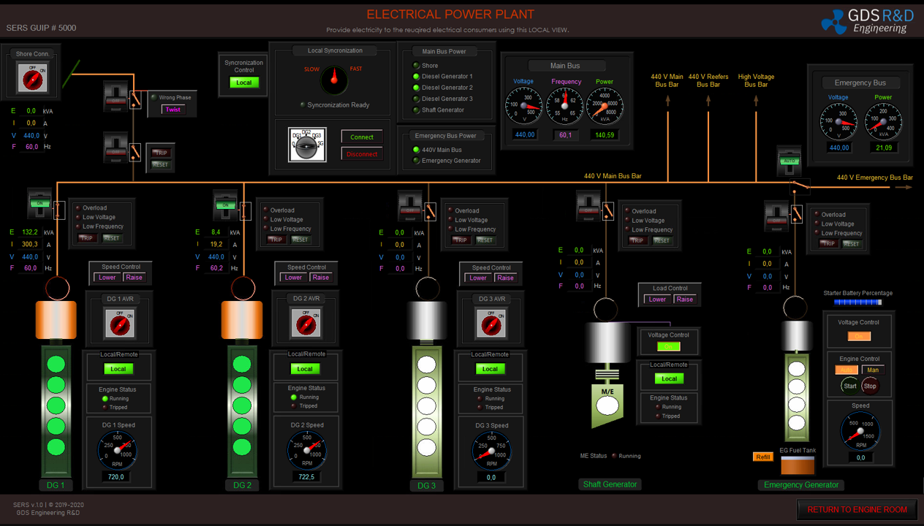

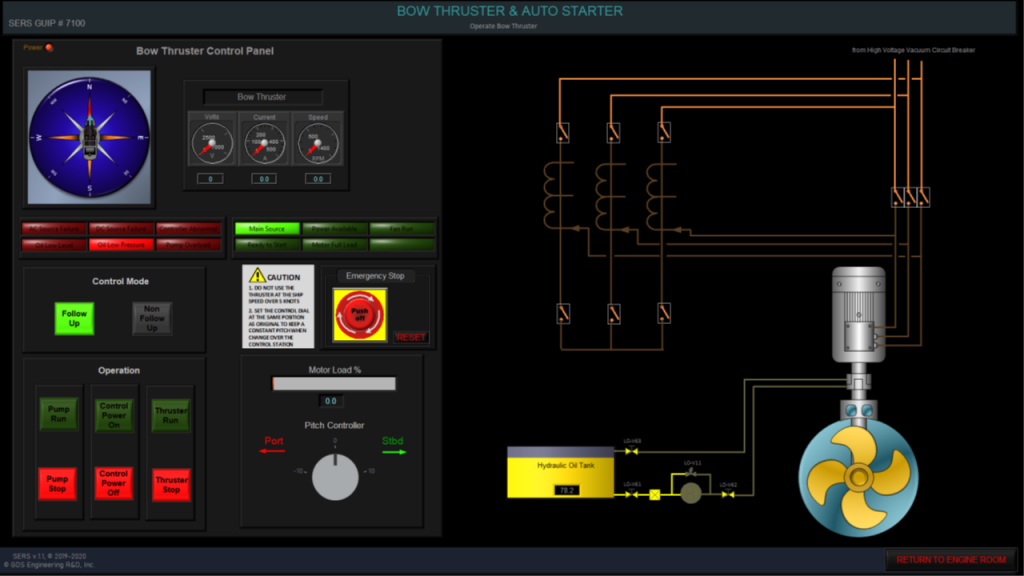

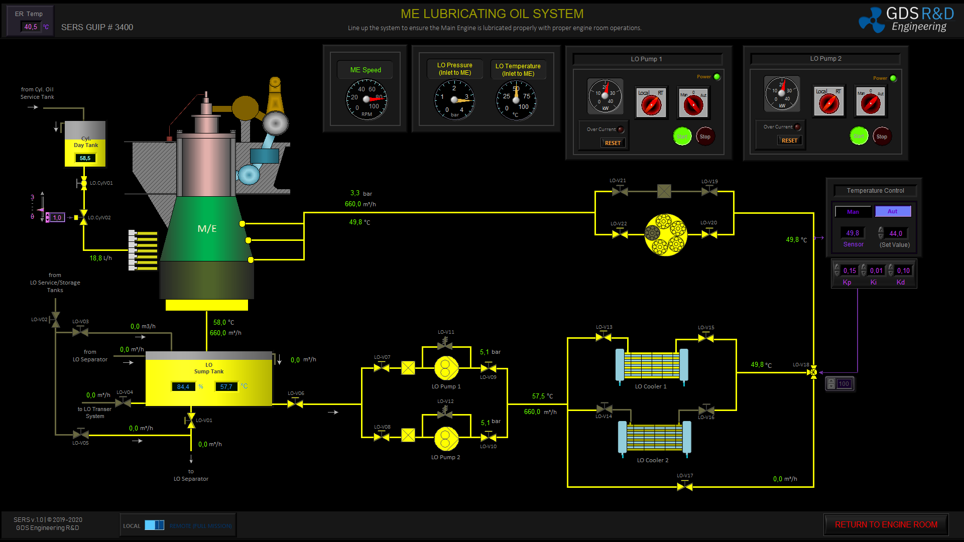

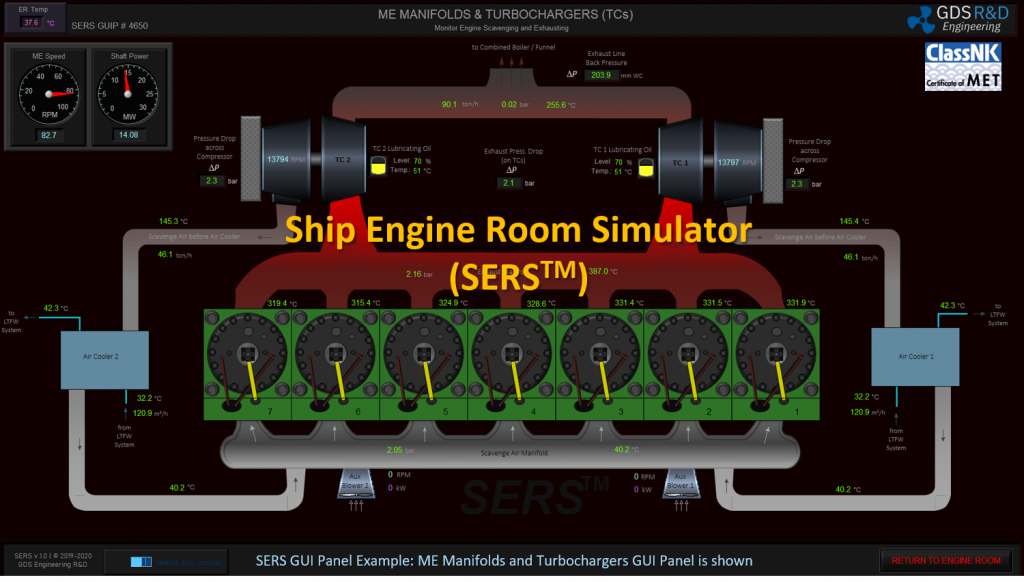

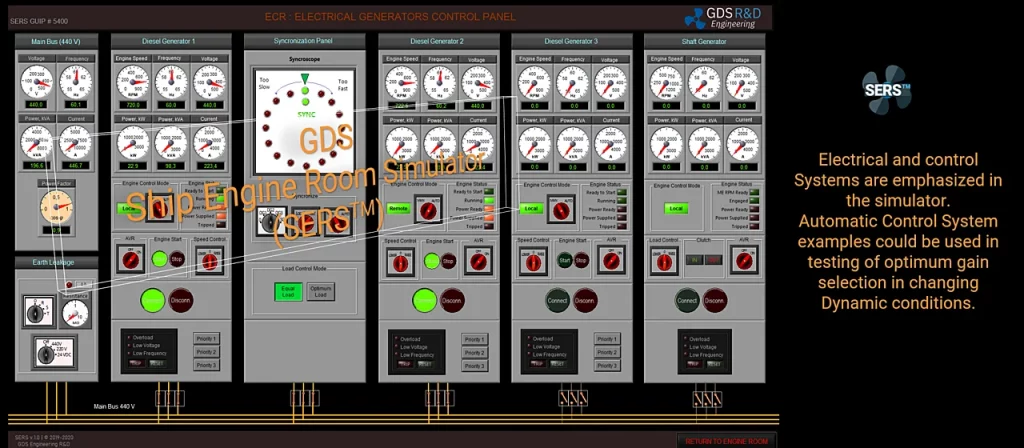

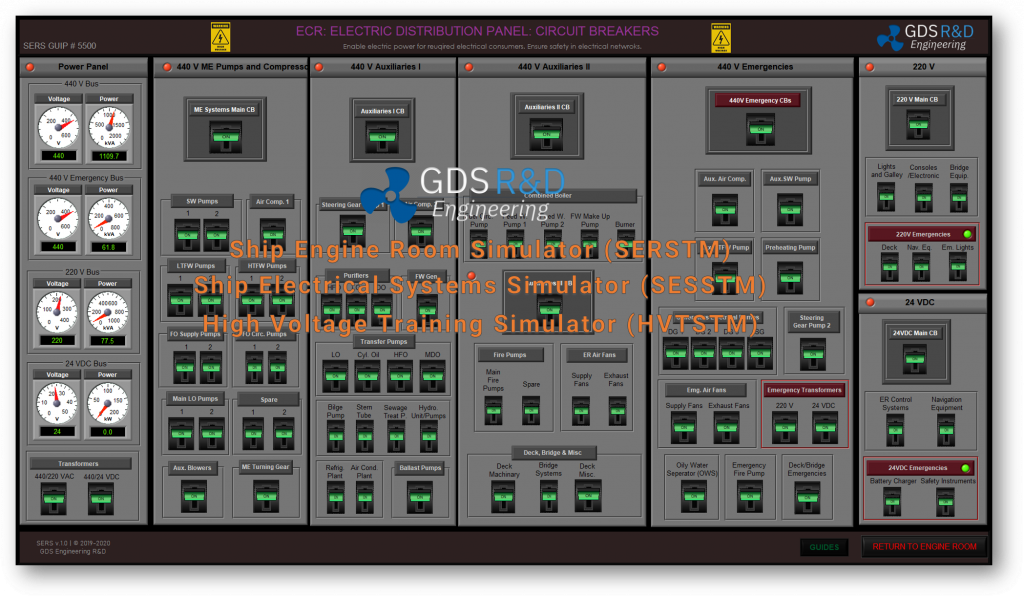

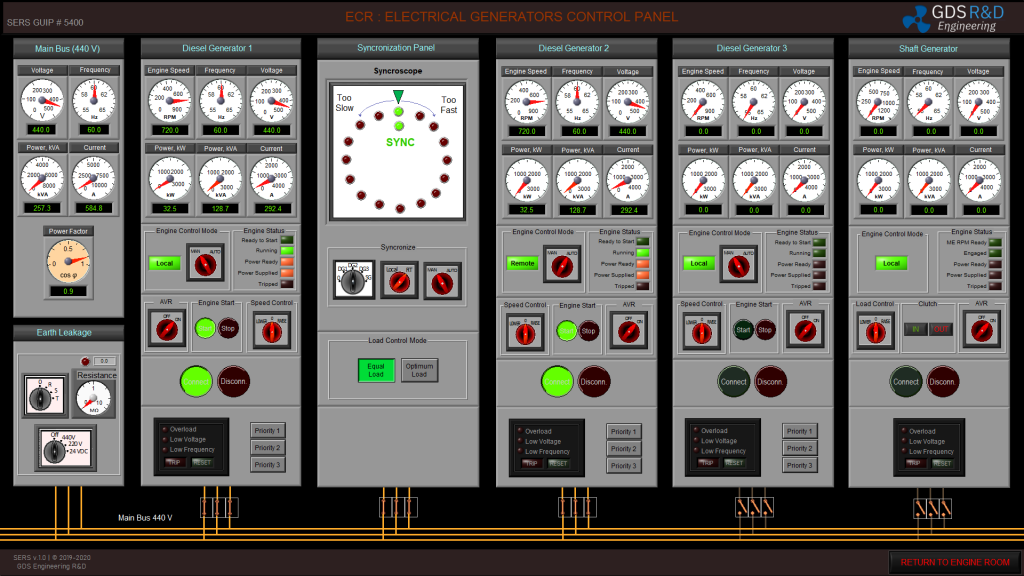

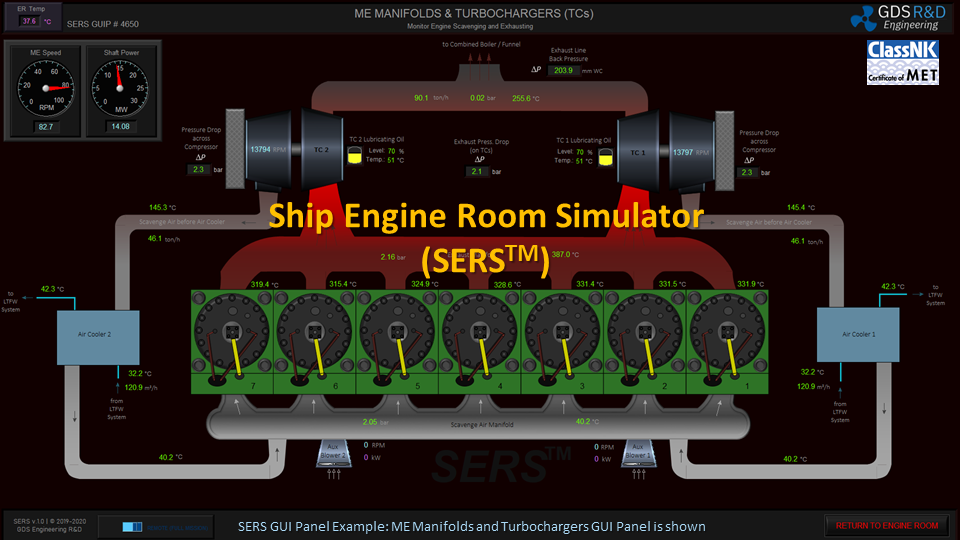

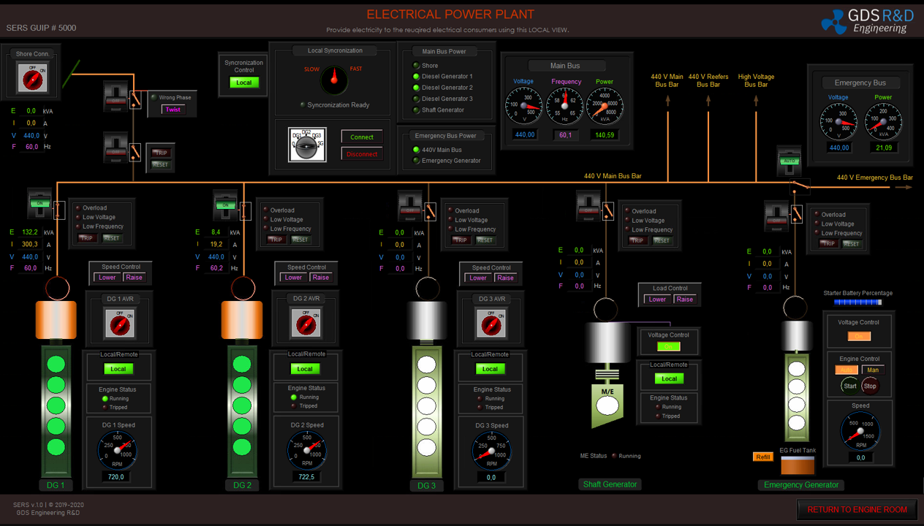

- Simulates all engine room machinery and systems with more than 50 GUI Panels.

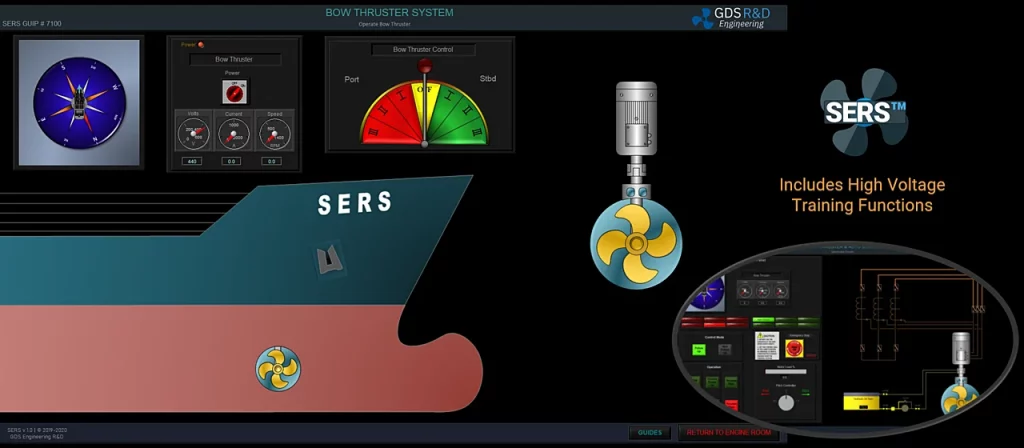

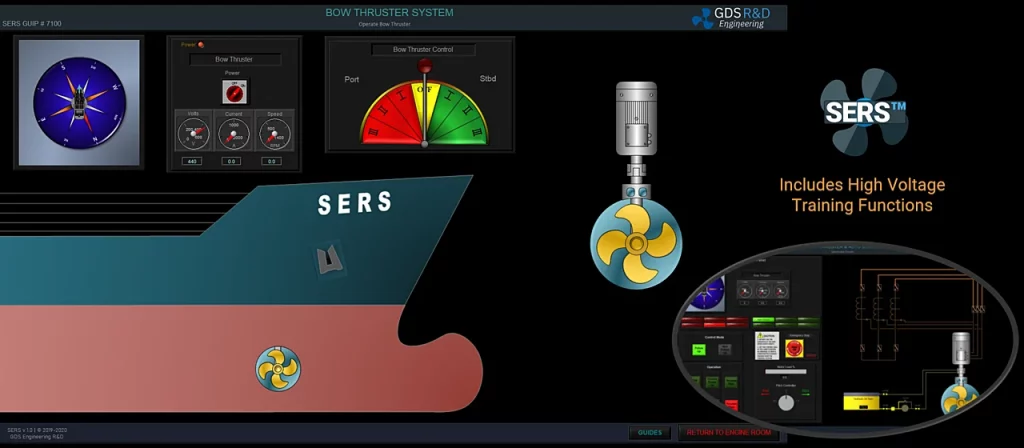

- Satisfies the High Voltage Training requirements.

- Includes Environmental Pollution modules, such as Ballast Water Treatment, Oily Water Separator, ME Denoxification System, and similar.

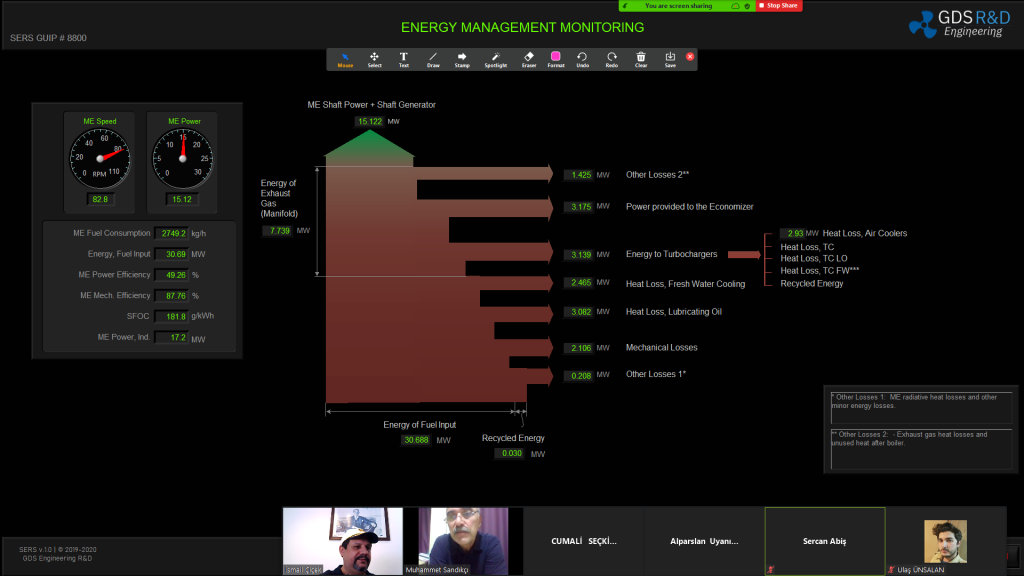

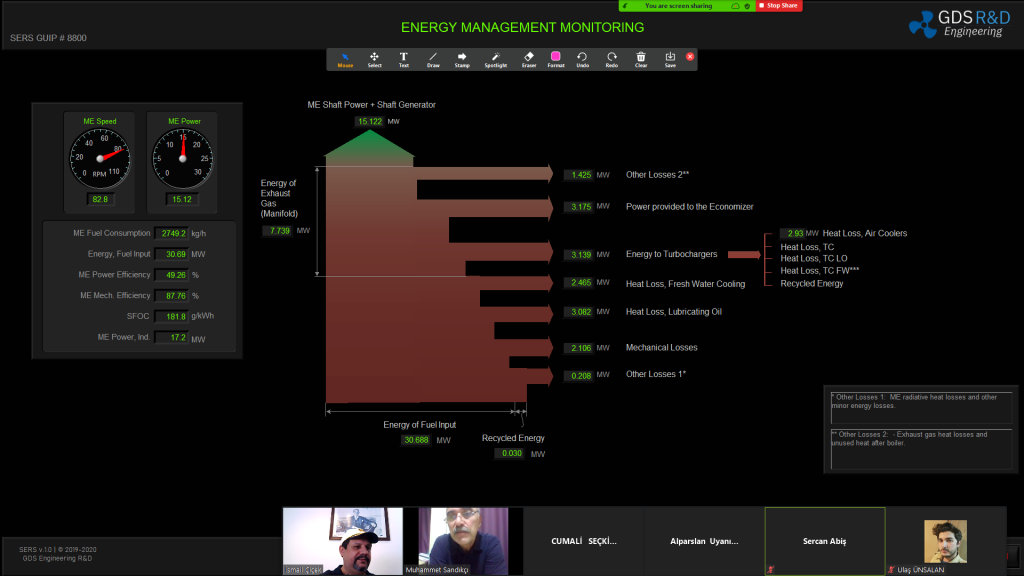

- Includes Energy Efficiency modules. Students can compare theoretical studies against the simulator instances using Sunken Diagrams.

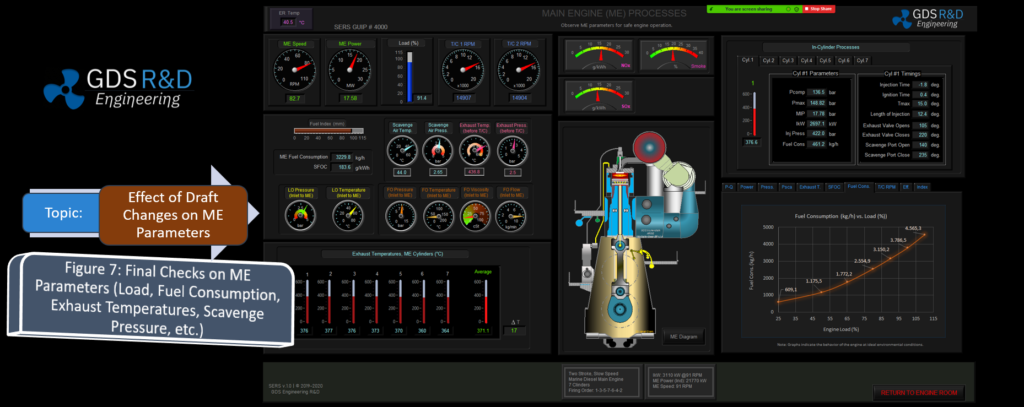

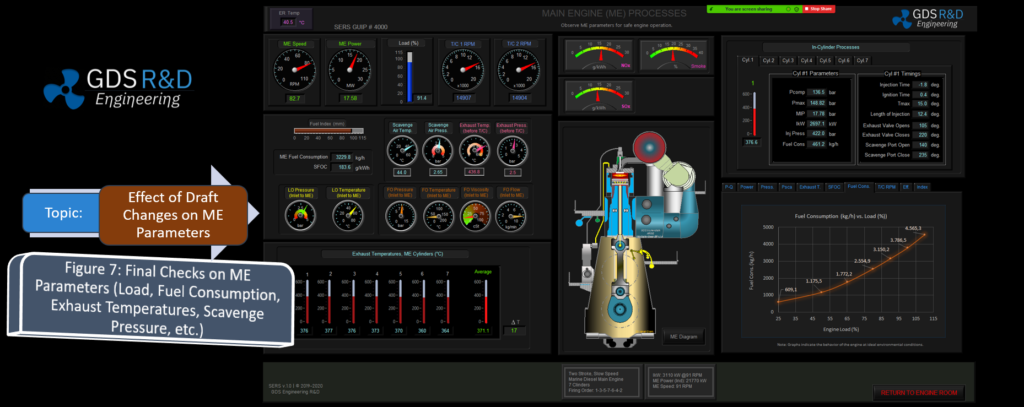

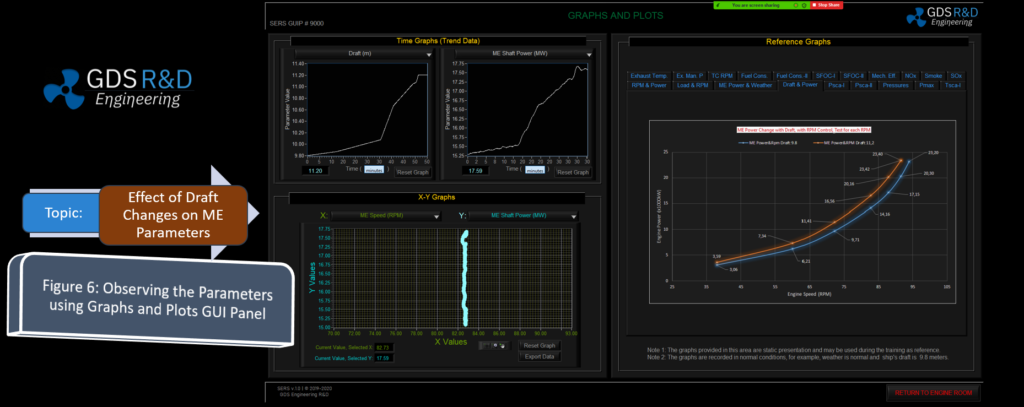

- Includes engine performance monitoring tools. Students are able to compare the current values againt the baselined ship’s navigation test as well as main engine’s factory test data. The baselined test data are presented within the software to the students with graphs. This our unique approach is to actually duplicate the real world work environment of wachkeeping engineering officers checking the parameters against the user manuals and engine books with test data.

- Provides a realistic environment for emergency operations with all required systems.

For reading an example of an IMO Model Course 2.07 exercise (effect of weather on engine performance):

- See the example of study executed by a student, DEMO VIDEO on our YouTube Channel

- Read the detailed step-by-step progress of the exercise described in our website page.

This page includes all information and links about the GDS Engine Room Sİmulator. Expand the acordion paragraphs below for reading the details collected under each topic.

Modular ER Panels for Distributed Type Simulator Training

SERS is Certified for Meeting IMO STCW 2010 Compentency Requirements

- Certified by ClassNK, an official member of IACS, in 2020.

- Certification type is Full Mission (Class A) type approval.

- Certification includes or exceeds IMO STCW 2010 (with Manila Amendments) training / competency requirements.

- Institutions can use the software as a lab tool for Operational Level Training as outlined in IMO STCW 2010.

- Institutions can use the Full Mission software as a lab tool for Management Level Training as outlined in IMO STCW 2010.

- Students can exercise for operat all IMO Model Course 2.07 exercises

- Student Exercise Workbook I includes Operational Level Exercies.

- SERS meets or exceeds IMO Model Course 2.07 exercise requirements.

- Satisfies the High Voltage Training requirements.

Certified for Meeting IMO Model Course 2.07 Exercise Requirements

- Certified for use in training and education of marine engineering cadets.

- Certified by ClassNK, an official member of IACS.

- Certification includes or exceeds IMO Model Course 2.07 (2017 Edition) exercise requirements.

- IMO 2.07 Model Course provides specific exercises covering both operational and management level training objectives. SERS provides all systems available to perform these exercises. Additionally GDS Team developed exercise workbooks that are used by the instructors. There are two exercises workbooks distributed with a SERS licence, which are

- Student Exercise Workbook I: Operation Level

- Student Exercise Workbook II: Management Level

- Each exercise workbook comes with more than 10 exercises. Each of the IMO Model Course 2.07 exercise description is referenced.

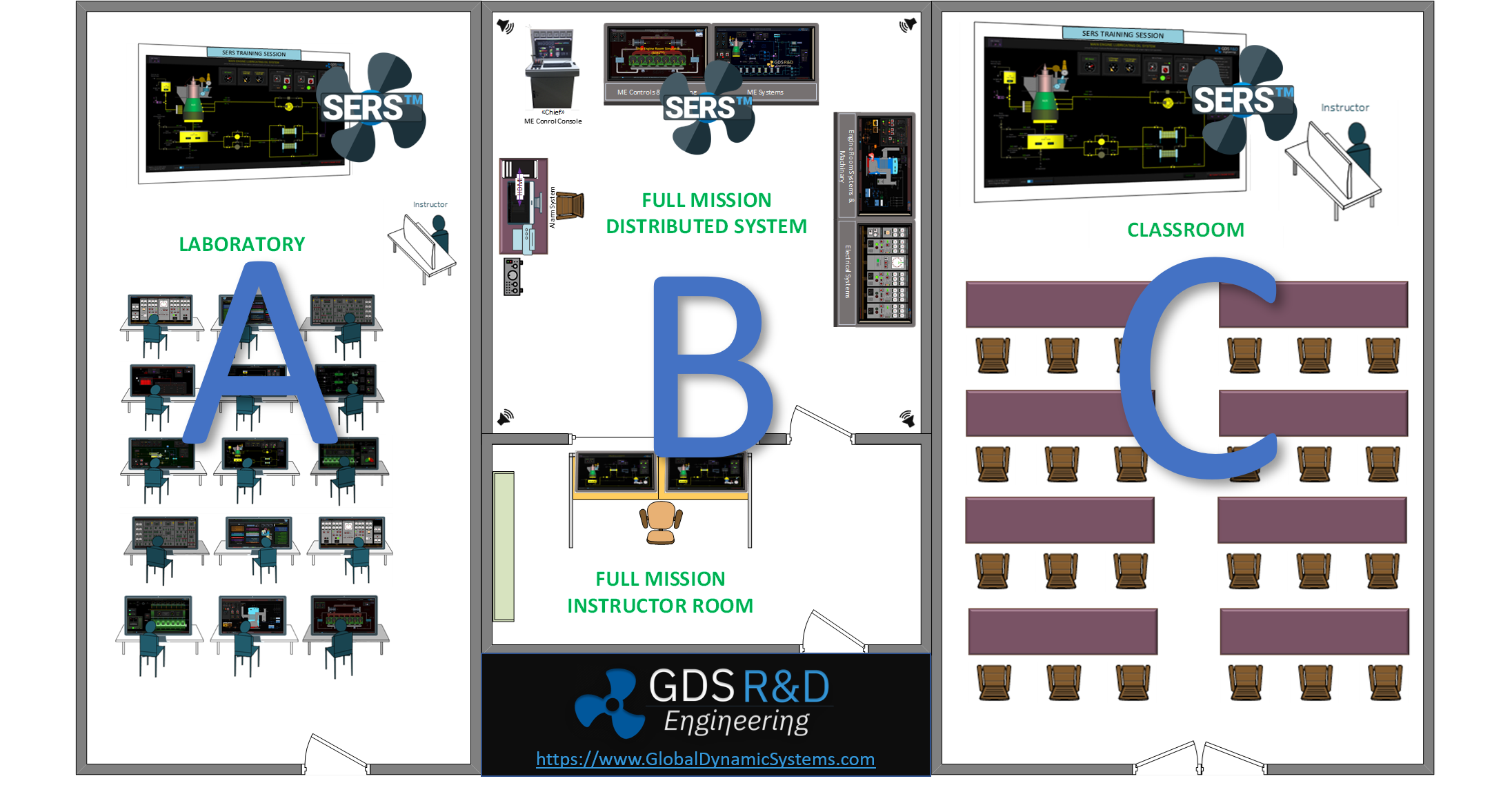

An example of layout arrangment for a complete ERS Training System using GDS SERS. This is a simplified example. The number of touch screen panels and control and monitoring consoles are insreased based on the training needs and demands.

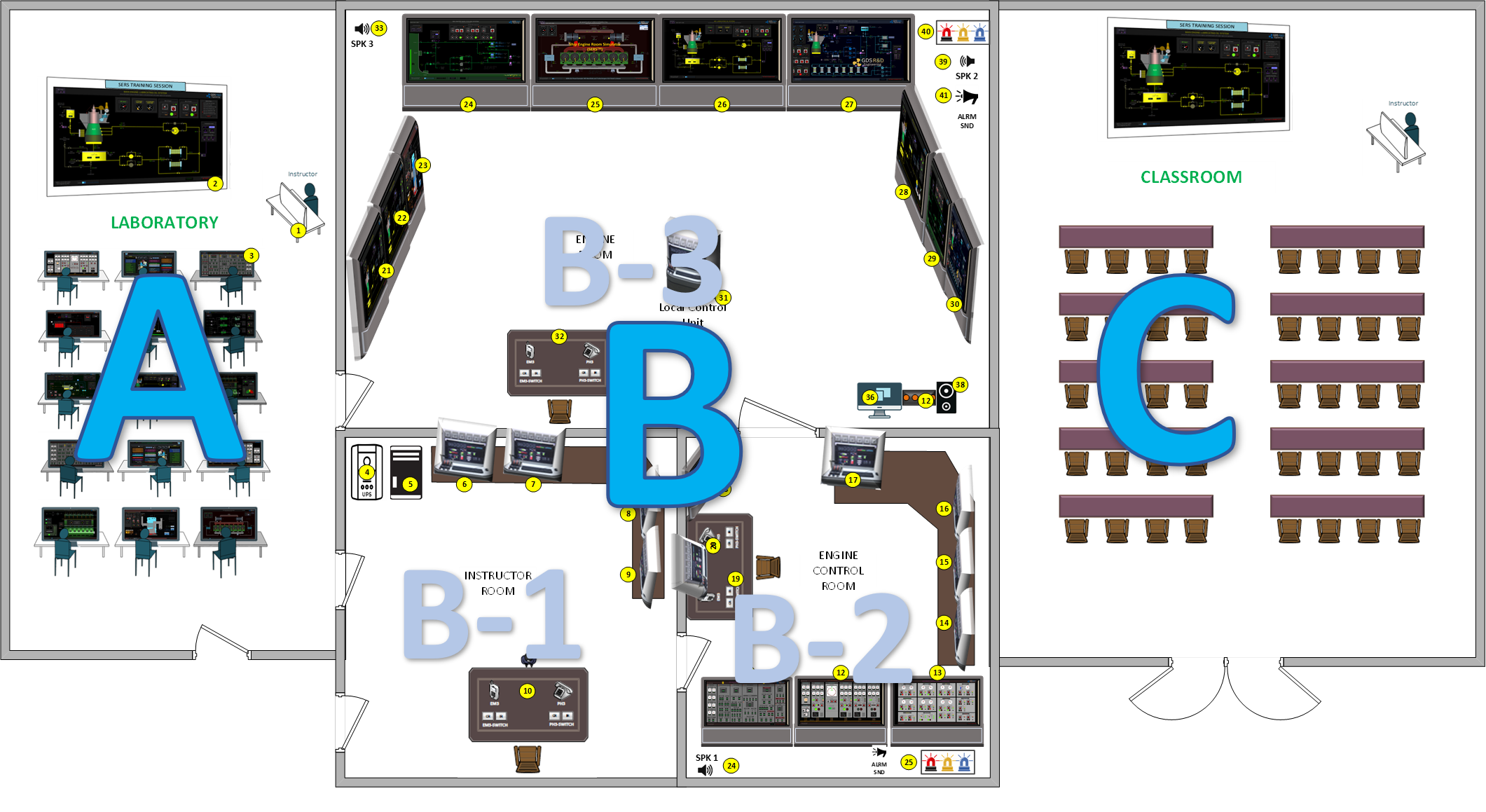

Anohter Team Training Layout Example: Sepated Engine Room (ER) and Engine Control Room (ECR) spaces. A total of 11 distributed large touchscreen panels are used in the ER with environmental effect such as lights, sounds, fans, etc. ECR can include large screen panels as well as hardware consoles with display gauges and engine control equipment. Electrical systems may be simulated via hardware consoles or using large touchscreen panels.

“The first step in teaching students to innovate is making sure that educators have opportunities to be innovators themselves.

”Suzie Boss, Bringing Innovation to School: Empowering Students to Thrive in a Changing World

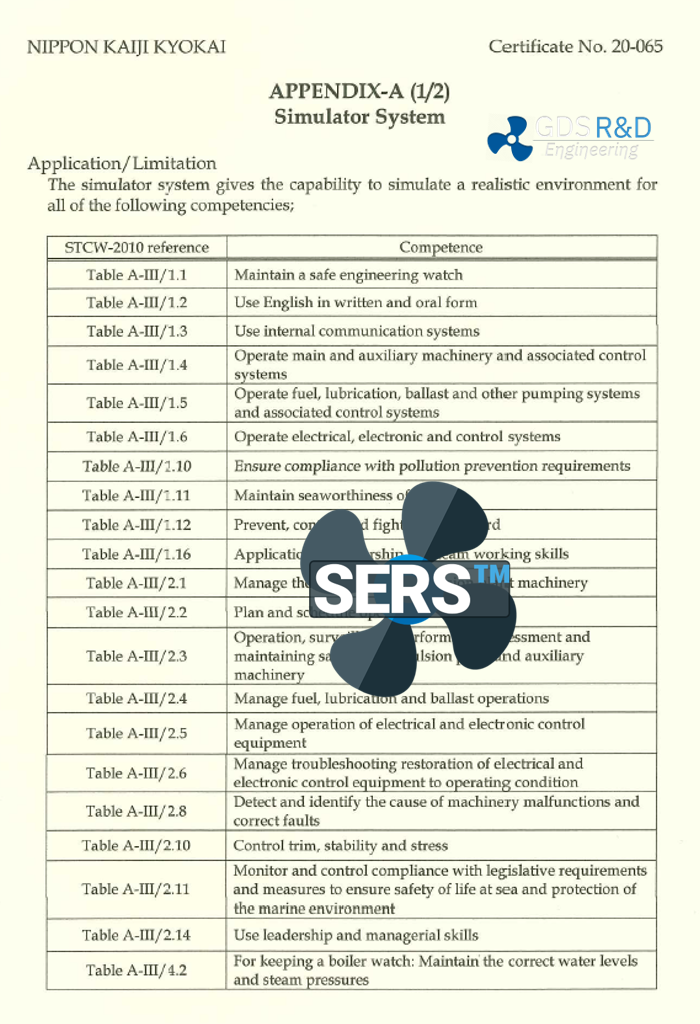

See the complee list of IMO STCW 2010 competencies that the SERS software meets or exceeds:

ClassNK certification includes the following IMO STCW 2010 Competencies:

| STCW-2010 reference | Competence |

| Table A-III/1.1 | Maintain a safe engineering watch |

| Table A-III/1.2 | Use English in written and oral form |

| Table A-III/1.3 | Use internal communication systems |

| Table A-III/1.4 | Operate main and auxiliary machinery and associated control systems |

| Table A-III/1.5 | Operate fuel, lubrication, ballast and other pumping systems and associated control systems |

| Table A-III/1.6 | Operate electrical, electronic and control systems |

| Table A-III/1.10 | Ensure compliance with pollution prevention requirements |

| Table A-III/1.11 | Maintain seaworthiness of the ship |

| Table A-III/1.12 | Prevent, control and fight fires on board |

| Table A-III/1.16 | Application of leadership and team working skills |

| Table A-III/2.1 | Manage the operation of propulsion plant machinery |

| Table A-III/2.2 | Plan and schedule operations |

| Table A-III/2.3 | Operation, surveillance, performance assessment and maintaining safety of propulsion plant and auxiliary machinery |

| Table A-III/2.4 | Manage fuel, lubrication and ballast operations |

| Table A-III/2.5 | Manage operation of electrical and electronic control equipment |

| Table A-III/2.6 | Manage troubleshooting restoration of electrical and electronic control equipment to operating condition |

| Table A-III/2.8 | Detect and identify the cause of machinery malfunctions and correct faults |

| Table A-III/2.10 | Control trim, stability and stress |

| Table A-III/2.11 | Monitor and control compliance with legislative requirements and measures to ensure safety of life at sea and protection of the marine environment |

| Table A-III/2.14 | Use leadership and managerial skills |

| Table A-III/4.2 | For keeping a boiler watch: Maintain the correct water levels and steam pressures |

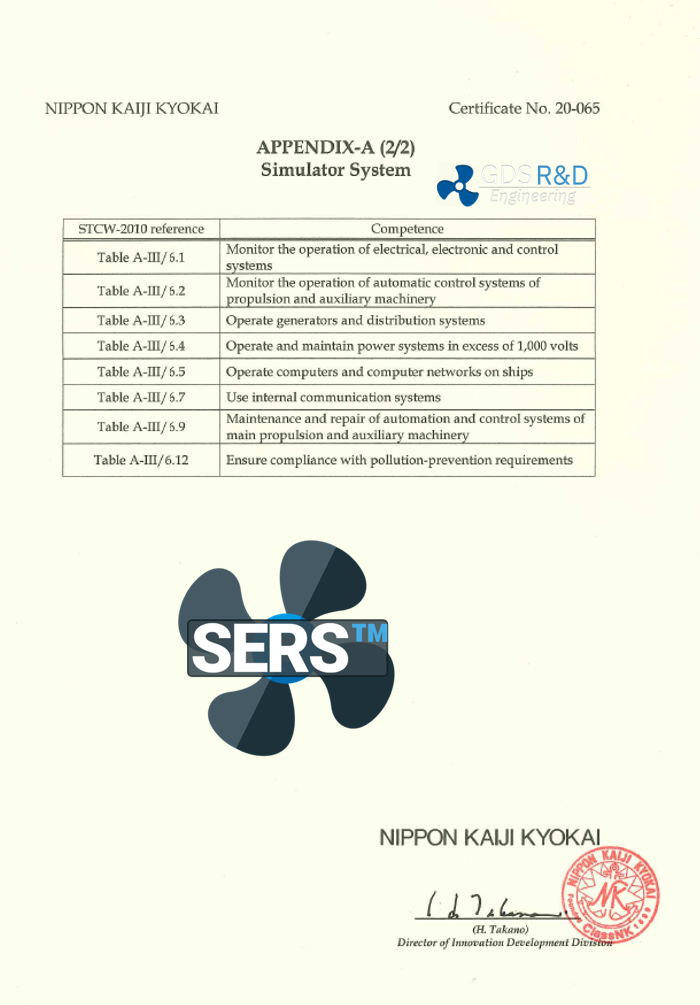

| Table A-III/6.1 | Monitor the operation of electrical, electronic and control systems |

| Table A-III/6.2 | Monitor the operation of automatic control systems of propulsion and auxiliary machinery |

| Table A-III/6.3 | Operate generators and distribution systems |

| Table A-III/6.4 | Operate and maintain power systems in excess of 1,000 volts |

| Table A-III/6.5 | Operate computers and computer networks on ships |

| Table A-III/6.7 | Use internal communication systems |

| Table A-III/6.9 | Maintenance and repair of automation and control systems of main propulsion and auxiliary machinery |

| Table A-III/6.12 | Ensure compliance with pollution-prevention requirements |

Allows for Remote or In-Class Training

Provides Two Engine Types

- Two Engine Types

- Traditional MC type main propulsion engine (MAN MC-C)

- Electronically/Computer controlled ME type of an engine (MAN ME-C)

- Ship propulsion system is provided by two types of engines, selected at the Initialization Panel, before starting the simulator software.

- Engine 1: A slow speed, 2 stroke, conventional diesel engine.

- Number of Cylinders : 7

- Firing Order : 1-3-5-7-6-4-2

- Bore : 700 mm

- Stroke : 2800 mm

- Engine Speed : 91.5 rpm & .20.7 MW @100% load

- Engine 2: Electronically injected engine, with the specification of the above listed engine, with the following additional panels

- Layout Panel, Hydraulic control units and local layout view

- Hydraulic Power Supply Layout

- Hydraulic Power Supply Pumps Local Control

- Filters, valves, shock absorber etc.

- Data Acquisition Unit / Main Operating Panel (MOP) Controller

- Process Monitoring Interface Panel

- ME Parameters

- Pressure-Crank Angle Graphs

- Pressure-Volume Graphs

- Pressure-Raw Data Graphs

- Balance Graphs

- Engine Reports

- Engine Reports, Save and Display Function, recorded in a historic filename order

- Main Operating Panel

- Alarms

- Engine (Operation, Process Information, Process Adjustment, Chief Limiters Panels)

- Auxiliaries Display Panel

- Maintenance Panel

- Layout Panel, Hydraulic control units and local layout view

- Engine 1: A slow speed, 2 stroke, conventional diesel engine.

Specific Operational and Management Level Exercises

Some examples are:

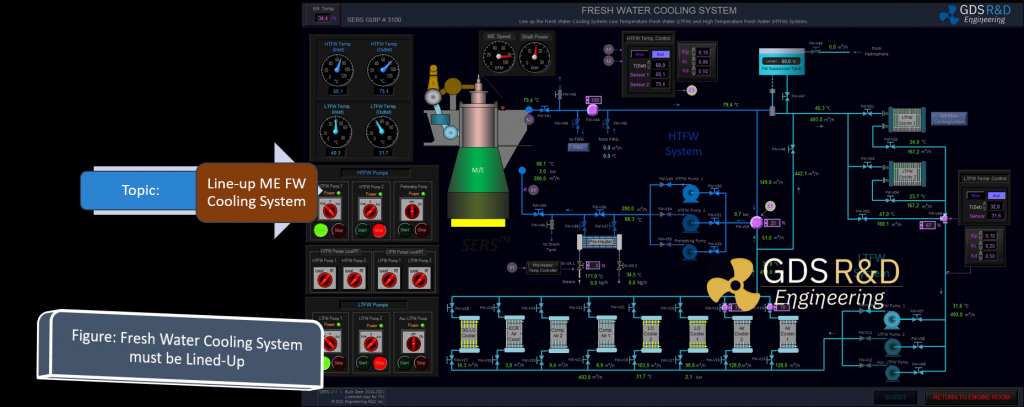

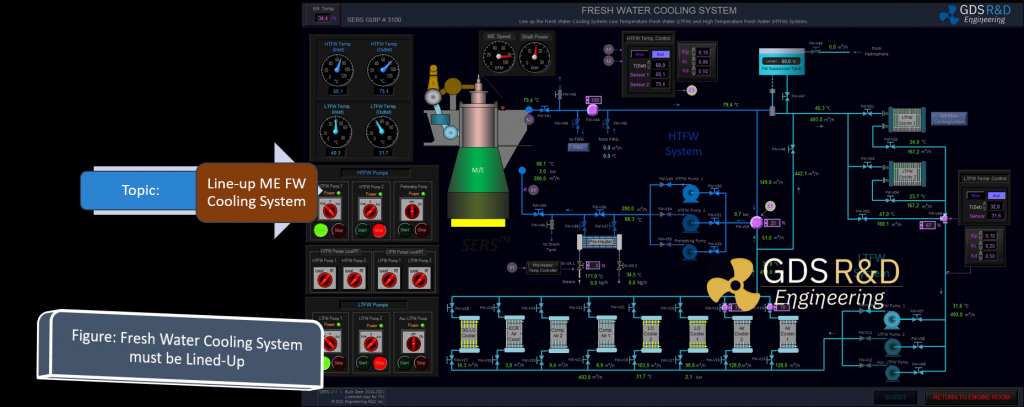

- Lining up all machinery and systems – all interactive

- Implements all ship operations with scenarious: Moving from port state to maneuvering – maneuvering to navigation – navigaion to anchorage, etc.

- Fuel operations – selection of low sulphur fuels and associated performance and operation activities

- LO operations – changing TBN and liner watch

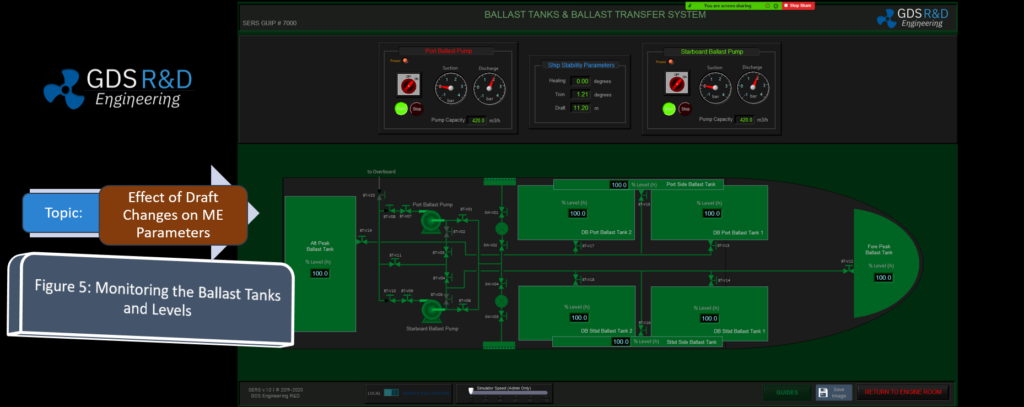

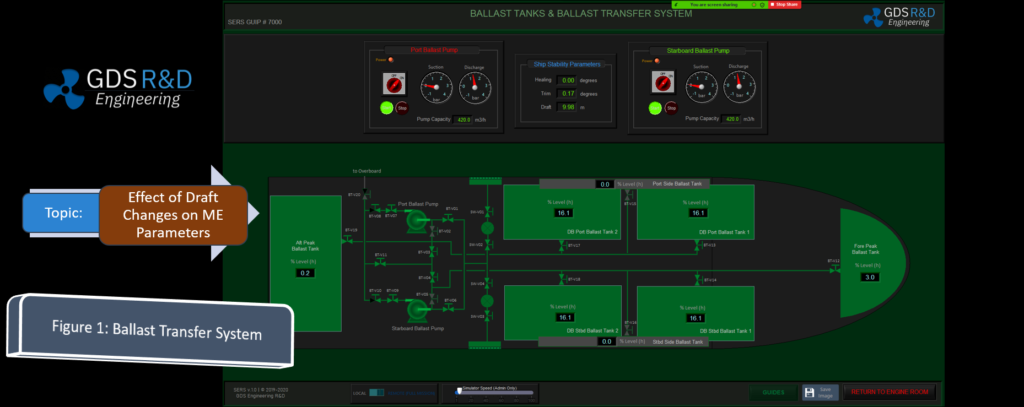

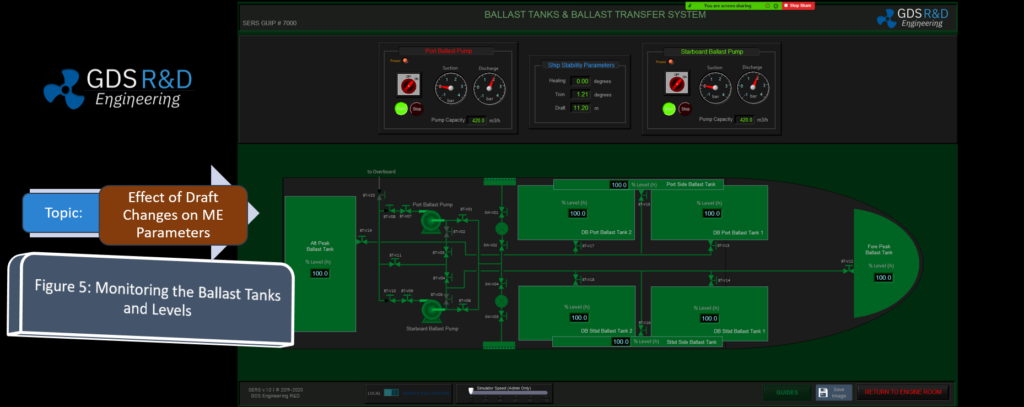

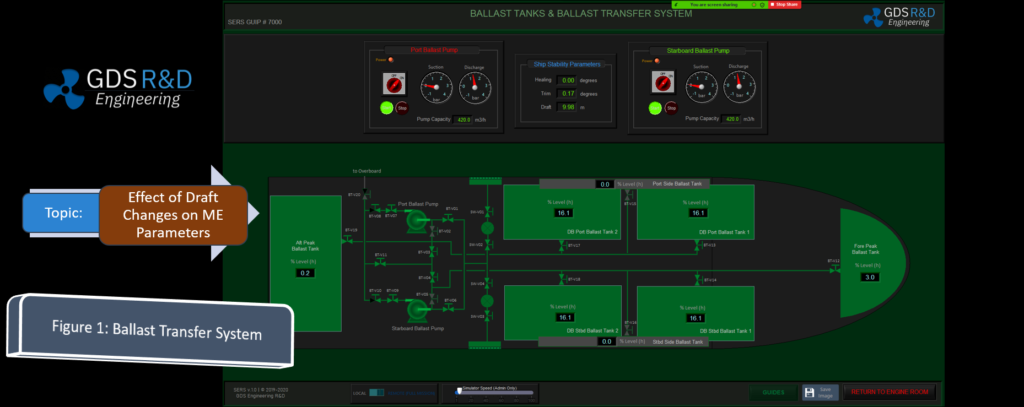

- Ballast system operations and Ballast Water Treatment

- Energy performance management and reporting

- Black out scenarios with many conditions

- Monitoring electrical system varibles, consumers, and setting the generators accordingly.

- Weather effect and engine performance study

- Lining up the shaft generator and criteria for navigation only with shaft generator

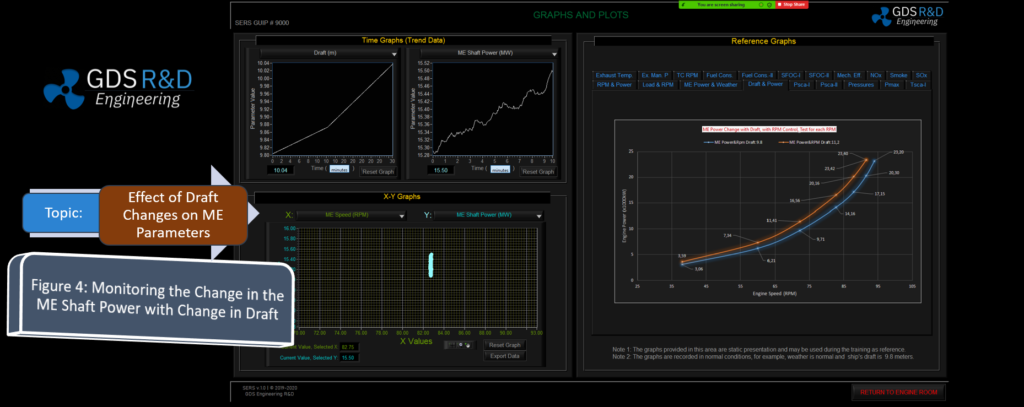

- Engine performance study with ballast operations

- Effect of Steering Rudder on Ship Performance

- Emergency operations such as fire and Quick Closing Valves

- and many more….

Unique Assessment Tools

- Provides automated student assessment tools

- Provides automated student exercise reports

- Activities are measured and repored to the Instructor

- Instructor can select the objectives and assign the exercises to any trainee. Click here to see a DEMO VIDEO in youtube.

- Instructor software includes Assessment Panel.

- The instructor can select exercise or exercises that have already been prepared and assign them to each trainee station.

- The instructor can create new exercise with Assessment Editor function.

- The instructor can determine allowed time for the exercise.

- The instructor can monitor exercise assessment.

- Trainee name, trainee ID, assigned objective(s), assignment status, initial condition, start time, allowed time, completion time, exercise(s) status, score, and grade can be monitored.

- The instructor can generate, display, and save assessment report. Also, the instructor can display previous reports.

Instructors Receive Five (5) Manuals and Two (2) Exercise Books

- Five User Manuals are provided

- Two Student Exercise Workbooks are provided

- Operational Level Training Exercises (IMO STCW 2010 / Model Course 2.07)

- Management Level Training Exercises (IMO STCW 2010 / Model Course 2.07)

List and Description of the User Manuals

SERS™ provides with a total of seven (7) user manuals, student exercise workbooks, and documents as complementary to the training practices. We provide these documents with a license purchase. Using the SERS™ document set in classroom study also promotes the real-world engine room best work practices.

SERS User Manual Vol I (Software Description) describes the SERS software with the SERS Graphical User Interface (GUI) Panels accessed from the SERS Main Graphical User Interface (GUI) Panel.

SERS User Manual Volume II (Engine Room Operations) includes the operational instructions on how to operate the engine room systems and machinery using the SERS. The training institutions can directly use the contents of this manual in their training procedures. There are also exercises included for use by the trainees for their own exercises and reporting.

SERS User Manual Vol III (Installation & Configuration) describes the installation and the configuration of the software and hardware items. Using this manual, configure to run as a Distributed System. The touch screen hardware panels are associated with the GUI panels using the configuration files.

SERS User Manual Volume IV (Instructor’s Manual) includes guides, information, and additional exercise tips for the instructors to utilize SERS in their trainings according to a specific training objective.

SERS Philosophy Document provides how SERS may be used in a curricula or in engine room simulator training programs. It provides guides for selecting the configuration of the SERS according to the training objectives.

Student Exercise Workbooks

Student Exercise Workbook, Volume I: We are already using the simulator in our own training programs. Volume I includes exercies that meets objectives of the IMO Model Course 2.07. Use Volume I for your Operational Level training objectives.

Student Exercise Workbook,Volume II: Volume II includes the Engine Room Management Level training exercises. Objectives are in accordance with IMO Model Course 2.07 and STCW competencies.

Also Provides Distributed System Simulating the Real Environment

- Any GUI Panels can be distributed to a large screen interactive panels.

- GUI panels can be grouped to reduce the number of touch screen monitors to use.

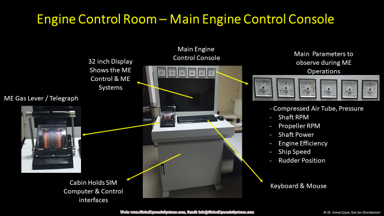

- Hardware consoles, such as Engine Control Console, are provided.

- The same software is used in all types of trainings

- Physical Workstations

- Remote/Online Version

- Distributed System

- Briefing / Debriefing System

- Instructor Workstation (can be used for both Physical or Online Trainings)

- The software has been developed in accordance with the addition of hardware (fans, room temperature, lighting, emergency lighting, etc.) that allow the control of simulator environment parameters. Hardware items and distributed system panels are additional functions, which are activated with a Distributed System license.

Watch our Youtube Video for Distributed System Demonstration https://www.youtube.com/watch?v=SrLSKpqcoRU&list=PLkPo-CGyn_VQpjiMDBZkB6yBwTgZIBaon&index=1&ab_channel=EngineRoomSimulator%28ERS%29CertifiedbyClassNK

GDS Engine Room Simulator Brochure: Click here to read or download…

Simulator Hardware (Computer) Requirements

- The recommended operating system is Windows 2010, 64 bit operating system environment.

- The software will be delivered with the installation CD or CDs and documentation containing installation instructions. Or software and documents may be realized with appropriate data transfer from GDS network locations.

- The software works well with a computer system equipped with at least the following features, such as an i5 processor and a 4GB video card with 4GB RAM. However, a better simulator performance can be achieved with the computer with better hardware. The means of better computer is to have better features of RAM, storage space, and graphic card.

- RAM: 4MB RAM, i7 processor

- Free Hard Disk Space: 256GB

- Display Card: DirectX 10 compatible with GPU, 4 GB

- Sound Card: DirectX 10 compatible sound card

- Monitor: 27 inch, widescreen with 16:9 aspect ratio. Resolution: 1920x1080p. Refresh rate: 60 Hz or higher

- The software is capable of operating smoothly with touch screens. All SERS engine room components, i.e. valves, pumps, pump controls, ON/OFF buttons, navigating between panels, etc. are activated with one mouse click. Therefore, as it is fully compatible with touch screen monitors, users do not need a keyboard for operating any of the aforementioned engine room component functions.

General Software Specfications

- The software language is English in accordance with IMO training standards and the maritime terms used are in accordance with the technical vocabulary and writing rules used in the practical English language in the sector. In fact, IMO STCW 2010 Competency for English is included in the certification of the ClassNK to promote this competency in the IMO level trainings.

| Table A-III/1.2 Use English in written and oral form |

- At least 1 administrator user is defined in the simulator software entry.

- Administrator can create new users with name, password, and user level (e.g. Trainer, Administrator, Trainee, etc.)

- An administrator level user can delete any user account.

- Setup and administrator functions are detailed in SERS User Manual Volume I.

- The user can start the simulator according to different ship initial conditions. Ship initial conditions and system initial functions are shown in SERS User Manual Volume II.

- The user can start software with a pre-recorded scenario/condition.

- The simulator can be started at Briefing/Debriefing Mode. It includes user activities saved high resolution of images corresponding to each trainee actions, recorded in a historic time order. Trainee or Instructor can use these files for briefing later. Briefing/Debriefing files consist of files that can be opened with standard Windows application programs, displayed, deleted with Windows operating system features or transferred to another environment, with user name, surname, ID and time content with date and second accuracy. When these files are used, it can be displayed visually which actions the trainee took in which time flow.

- During the operation of the simulator, a training report with name, surname, ID and time sensitive accurate to date and seconds is automatically generated for each training. The resulting training report is according to the historical order of the trainee’s actions and has the features that action times can be derived.

- Simulator software simulates a typical commercial long-distance ship’s machinery and systems. Ship, machinery and systems simulated are detailed in User Manual Volume I and SERS Brochure.

- All parameters in the software have been developed as related and interactive (integrated). For example, tank heating is realistic, depending on the system parameters in the boiler and the positions of the valves. Another example is that when the diesel generator collapses and black out occurs, the entire electrical system and its consumers react accordingly, so that the system can be re-operating training (IMO Model Course 2.07, in accordance with realistic ship operating principles, etc.)

Instructor Station

- The instruction’s software can be installed on the same computer with SERS software or on a separate computer.

- Malfunctions or events can be selected and applied by selecting their application times. Malfunctions are listed in the manuals and examples are given.

Monitoring SERS Stations

- During a selected simulation run on SERS computers installed in a classroom with the Instructor Software:

- Main engine parameters and other critical engine room system parameters (e.g. steam pressure in the boiler, ME lubricating oil inlet pressure and temperature, main engine speed, power, turbocharger speed, etc. and parameters showing the status of auxiliaries) can be seen. Instructor Manual (SERS User Manual Vol IV) lists all monitored parameters and other functions of the Instructor Software.

- The instructor can inject a malfunction or create a scenario from the Instructor Station.

- Main engine and other critical malfunctions (e.g. ME cylinders injection time late, nozzle wear, piston rings wear, diesel generators LO Filter dirty, LTFW Pumps Overload, HTFW Pump Overload etc.) can be injected from SERS Instructor Station Panel. Instructor Manual (SERS User Manual Vol IV) lists all malfunctions.

General Training Functions

- All SERS Graphic interface panels are suitable for efficient use, the system and circuit diagrams are simple and developed and understandable according to the plans and principle of commercial ships.

- Valve types, filter types, tanks, pump types, compressor types, air tubes (reservoirs), gauge types, hydraulic and pneumatic symbols used in system and circuit diagram are selected in accordance with international “Piping and Instrumentation Diagram” (P&ID) standard diagrams and operates are simulated.

- The colors (pipe, etc.) are made in accordance with the colors conventionally used in commercial ships (e.g. seawater system-green, fire system-red, freshwater system-blue, lubricating oil system-yellow, fuel system-orange, etc.)

- Main Engine Control can be provided from the following locations:

- Engine Control Room (ECR)

- Bridge

- Local Control

- Operations of the system components in the engine room are compatible with real ship operations. (For example, pumps can be controlled both locally and remotely.)

- Sufficient data (pressure, temperature, flow rate, power, etc.) are shown for each system in the software and these data have been tested to be the same as in realistic system/factory test results.

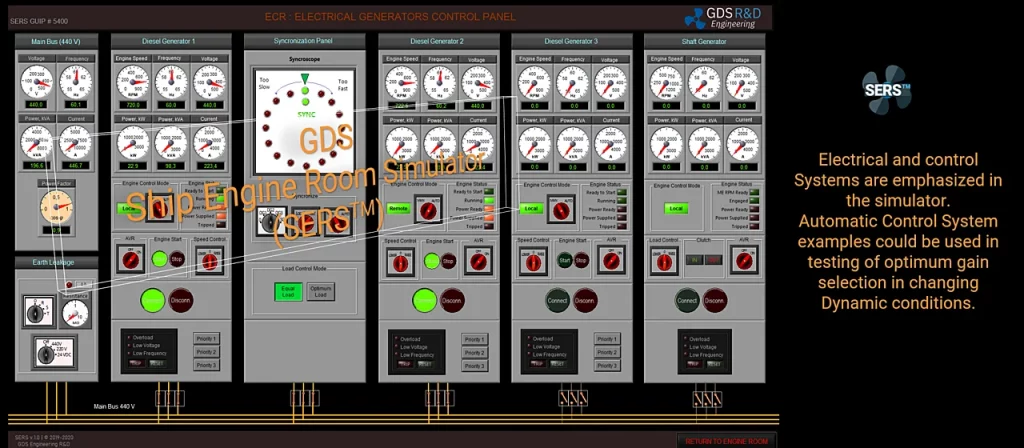

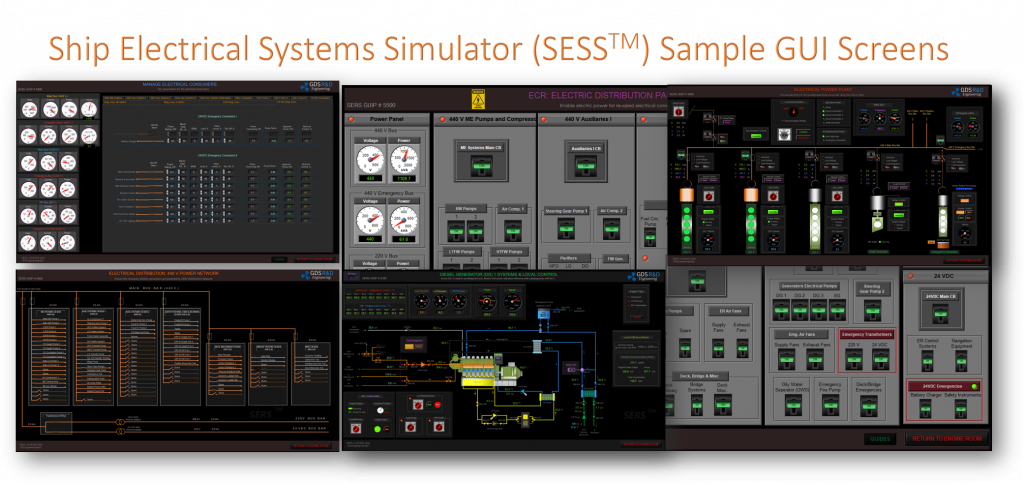

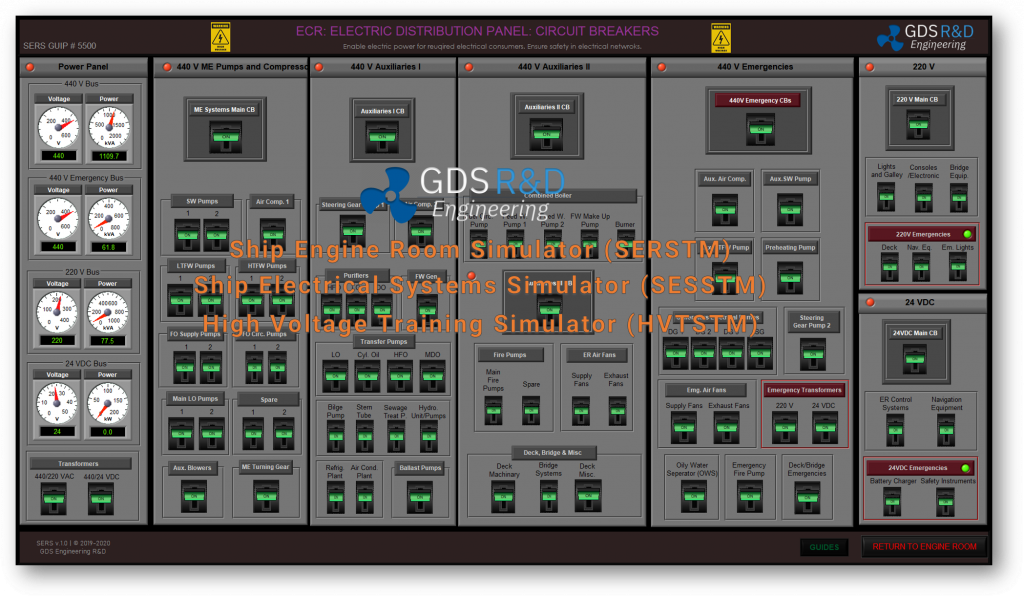

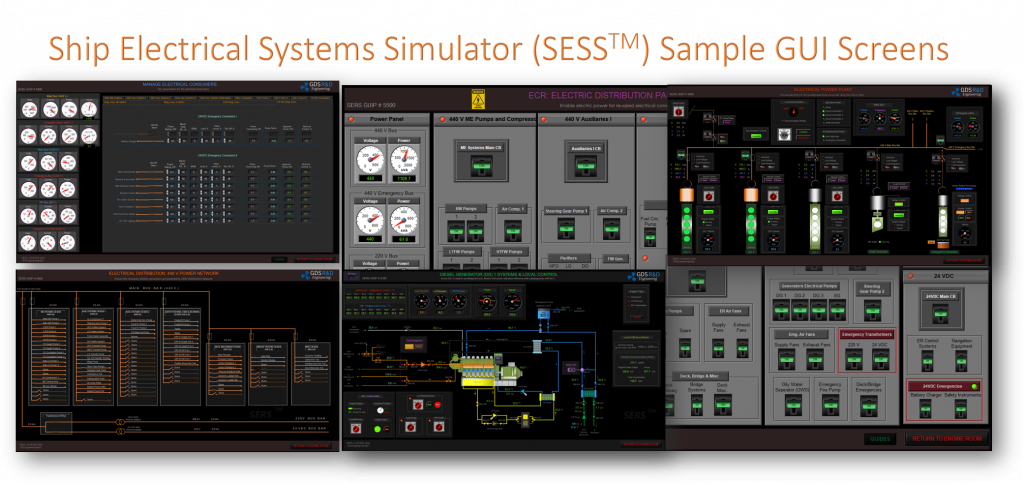

- The following systems and operations have been simulated with graphical interfaces for the entire electrical system in order to provide Ship Electrical Systems Training:

- 3 Diesel Generators

- 1 Shaft Generators

- Emergency Generator

- Generators Remote Control and Synchronization Panel

- Circuit Breakers

- Voltage, power, current, frequency, etc. gauges

- Pumps and compressors local and remote control panels

- Engine room electrical consumers and electrical specifications

- Other electrical consumers on the ship such as reefers

- 440V AC distribution network and consumers

- 220V AC distribution network and consumers

- 24VDC distribution network and consumers

- Other electrical power systems

- Shore connection

- Engine room fans have been simulated, and in case of not working, the engine room pressure changes and its effect on the main engine is demonstrated.

- Engine room temperature, seawater temperature, etc. parameters can be changed and the systems operate accordingly.

- Main engine control has RPM and FUEL CONTROL modes.

- SERS provides determining thermal efficiency and developing heat balance diagram of the simulated main engine. (see Section for IMO Model Course Exercises for details)

- The main engine pre-warning and SLOW DOWN and SHUT DOWN criteria are determined and the main engine operates accordingly.

- Systems belonging to the main engine, listed below, are shown on separate graphical interface screens and their operations can be performed in accordance with reality. The operations of the systems are described in User Manuals. For example,

- Main engine fuel system. The main engine fuel system supplies fuel to the main engine according to the fuel properties in tanks. The fuel system must be viscosity controlled.

- Main engine lubrication oil system. It has a lubrication oil cooling and control system.

- Main engine cooling water system (Central system includes HTFW<FW systems)

- Main engine local control system

- Main engine bearings monitoring and oil mist detector

- Main engine parameters monitoring screen includes graphs and values for main engine status such as P-θ and P-V.

- Systems in the engine room of a typical merchant ship and at least listed below are shown separate screens and their operations can be performed in accordance with reality:

- Seawater cooling system

- Freshwater cooling system

- Boiler system and steam circuit, fuel heating, tanks heating, etc.

- Compressed air system

- Lubricating oil, fuel oil, sewage, freshwater tanks and transfer operations

- HFO, MDO and LO Separators

- Stern tube system

- Ballast tanks and ballast transfer operations

- Freshwater tanks, freshwater and hydrophore system

- Bunkering operations

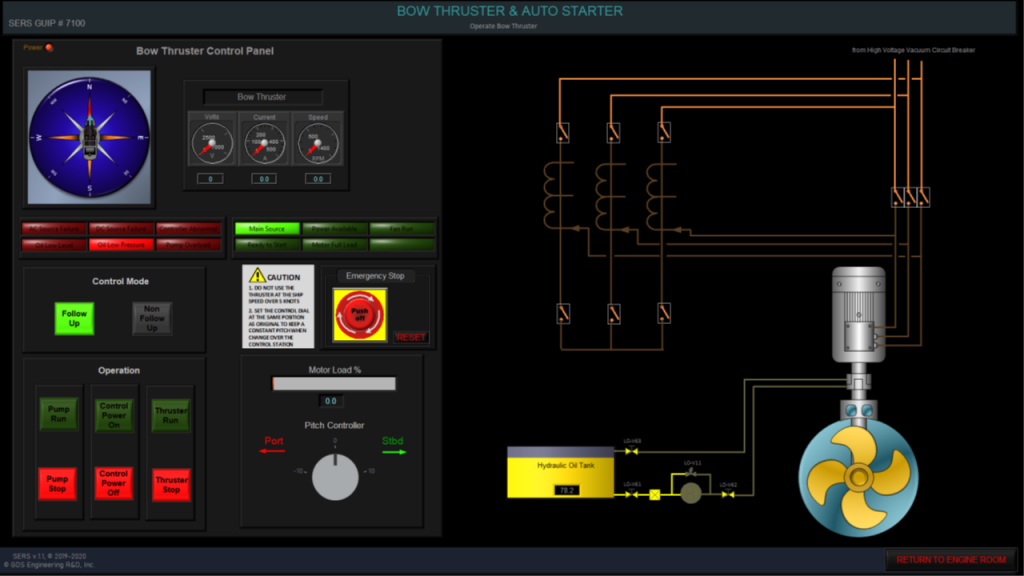

- Bow thruster

- SERS includes the ship safety systems listed below and operations of the listed systems:

- Main and emergency firefighting systems

- CO2 fixed fire installation

- Emergency response station and quick closing valves with system connections

- SERS includes the environmental safety systems listed below and includes operations of listed systems:

- Oily water separator

- Sewage treatment system

- Denoxification system

- NOx, SOx, and smoke monitoring parameters

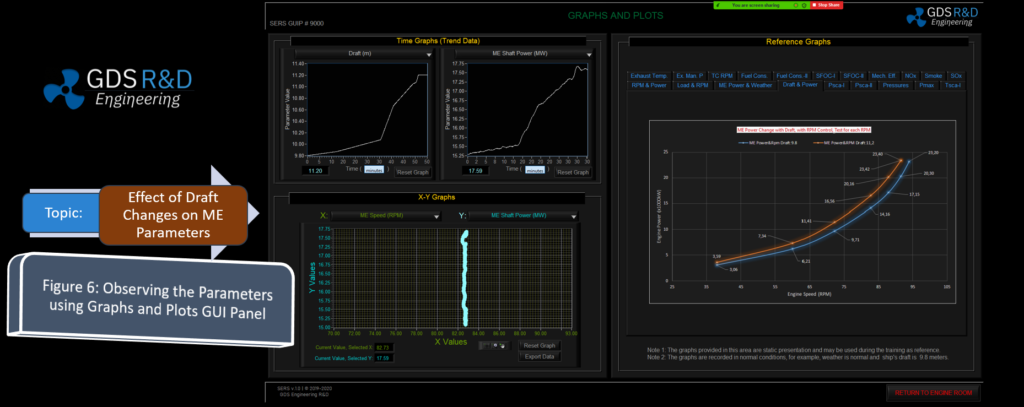

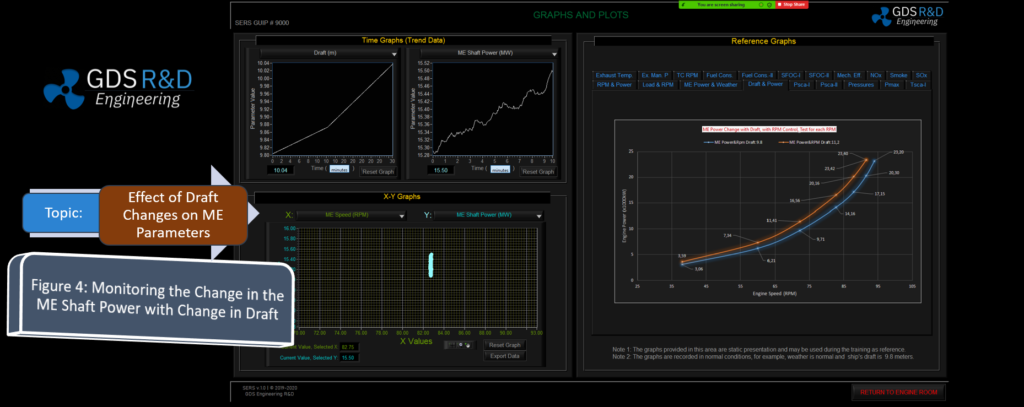

- Graphs and Plots Panel allows for plotting the main engine and engine room parameters on time graphs or plotting two variables against each other (X-Y Graph). This function allows for monitoring parameter trend data over time and useful while IMO Model Course Exercises are being studied.

- Simulator should include alarm panels and alarm log. The alarms that should be in the engine room of the ship were applied according to the class rules. Routine operations such as alarm system, SILENCE, ACKNOWLEDGE are implemented. Alarm values can be changed by user.

- Alarms Panel includes:

- Each system alarms with visible and audible indicator.

- Alarm code, parameter name, status, current value, alarm low limit and alarm high limit

- Alarm Log

- Alarm log keeps the list of alarms sounded in the engine room in accordance with reality.

- Alarm log can be saved and printed.

- Each system alarms with visible and audible indicator.

Our Vision in the Development of the ERS

ERS trainers developed Ship Engine Room Simulator ( Ship ERS of SERS™) with over 20 years of Engine Room Simulator (ERS) training experience in the Maritime Education and Training (MET).

We have combined both of our onboard work and academic experience with a high level of software engineering expertice. We have ended up with this state-of-the-art product for your effiency in training management.

With our product, our purpose is to ensure that the Instructors can efficiently utilize this training environment in their Maritime Education and Training (MET) programs and that the trainees can have productive learning outcomes.

Dr. Ismail Cicek

Wacth our Demo Youtube Videos (student exercises demonsrated by the students)

Demo videos available to watch in our YOUTUBE CHANNEL.

- Assessment Module: DEMO Video in YOUTUBE, , presented by a marine engineering student.

- A student is working on a Model Course 2.07 exercise: Effect of Weather Change: Marine Engineering Education and Training Using GDS SERS: DEMO VIDEO, presented by a marine engineering student.

- ERS, Engine Room Simulator: Engine Room Operations II: ME Preheating and ME Preparation, DEMO VIDEO IN YOUTUBE, presented by a marine engineering student.

- Engine Room Simulator ERS: Lubrication Oil (LO) Separator: Lining up and Operations, DEMO VIDEO IN YOUTUBE, presented by a marine engineering student.

- Lining-up systems from COLD Ship to Navigation: DEMO VIDEO IN YOUTUBE, presented by a marine engineering student.

- Lining-up systems from COLD Ship, Boiler Operations: DEMO VIDEO IN YOUTUBE, presented by a marine engineering student.

Some of our Articles on Ship Engine Room Simulator:

Display or download GDS ERS Brochure.

Capture GDS Vision in the ERS Development.

A page for more reading on the SERS, including IMO Model Course 2.07 exercise list.

Our Customers and Collaborations

A Summary of GDS SERS charateristics

Effect of Weather on the Marine Propulsion Engine Performance Onboard a Ship: An IMO Model Course 2.07 exercise, completed using SERS, shown with captured images taken during a student’s training.

A Study of the Main Propulsion Engine Performance with Ship’s Draft Change: An IMO Model Course 2.07 exercise, completed using SERS, shown with captured images taken during a student’s training.

Operating Marine Diesel Engines – IMO STCW 2010 Competency Requirements: MEDIA Page.

Ship Systems and Energy Management for Performance and Cost Savings: An IMO Model Course 2.07 exercise, completed using SERS, shown with captured images taken during a student’s training.

ERS Exercise Workbooks and Manuals in your Operational and Management Level Trainings: Students Love it! A complete list of GDS SERS manuals and exercise books distributed with license agreement.

An Advertisement Compaign Video of ITU Maritime Faculty: Forware the video to 2min. 47th seconds to see a testing of one of our simulator setup, in youtube.

We also provide other marine engineering e-Modules and simulators. Check out the complete list below.

Maritime Simulator Products

(SERSTM)

SERSTM is a certified, advanced, and Full Mission engine room simulator that can be used in both laboratory and distributed team environment training.

Click to read more about SERSTM.

SESSTM is a software simulation of all electrical systems in a typical engine room. It can be used as a laboratory software or in-class demonstration software.

Click to read more about SESSTM.

HVTSTM is a software, which can be used in the training of high voltage operations onboard a ship, such as Vacuum Circuit Breaker, Transformer, and high power loading to the main bus.

Click to read more about HVTSTM.

(VPLTM)

VPLTM is software, which supports the laboratory sessions of Physics I and and II experiements, which are mechanical and electrical experiments, respectively.

Click to read more about VPLTM sotware.

References of GDS Simulator Users

&

Solution Partners

in

Maritime Training and Research

|  |  | ||

|  | |||

|  | |||

|  |  | ||

|  |  | ||

|

We are looking for country/area representatives!. Please contact us for any of your interests.

Pingback: Yerli ve Milli Gemi Makine Dairesi Simülatörü SERS™ artık Malezya’da