Develop your P&ID Diagrams and GUI Panels Using GDS Components Library for LabVIEW

GDS Components Library for LabVIEW includes programmable Graphical User Interface (GUI) objects for LabVIEW development environment. Library includes components for pumps, pipes, valves, compressors, separators, engines, fluid and air system components, etc. Using the component library, visual LabVIEW programming is much easier and elegant. See GDS Ship Engine Room Simulator (SERS™) product pages to see example use of the visual components.

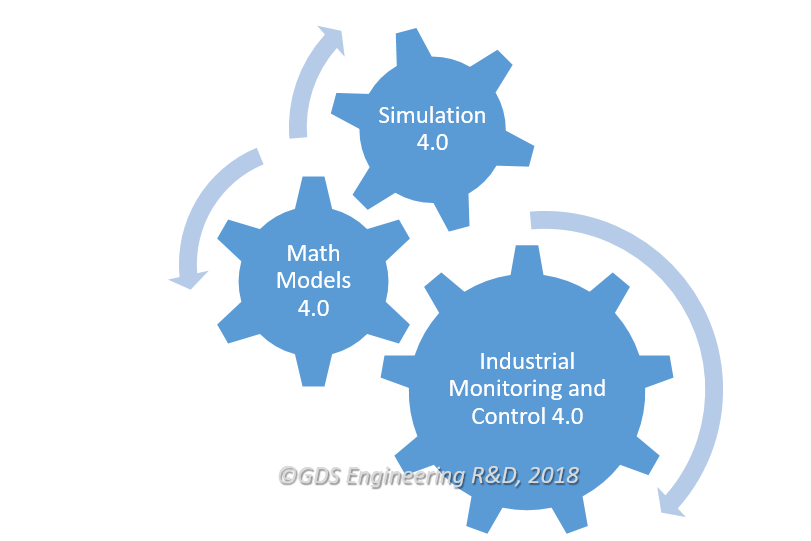

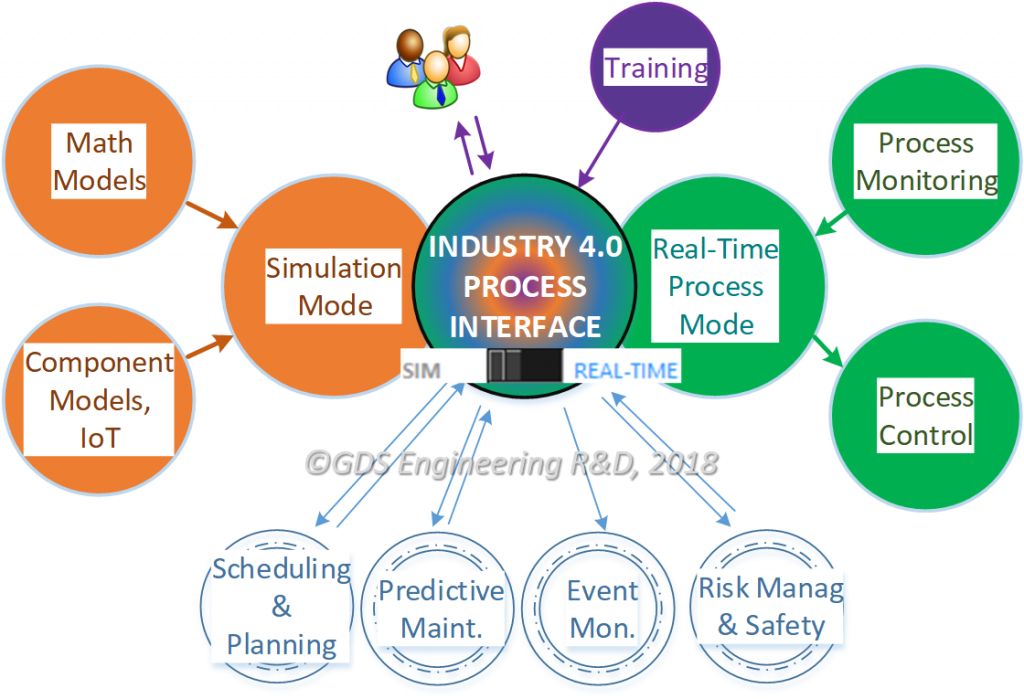

Our Industry 4.0 Tools and Mathematical Models are ready for use by LabVIEW Users, Systems Developers, and Plant Managers! Read below and contact us for more information and how to acquire our products.

We, GDS Engineering R&D, develop simulation of platforms, using engineering principles, thermodynamics, heat transfer, fluid mechanics, and such. An example of such a simulation system in shown in Figures on this page or see our simulators developed using these components in our PRODUCTS pages. Our simulation expertise, included but not limited to, diesel engines, generators and electrical use, lubrication systems, cooling systems, heating systems, hydraulic and pneumatic systems, pumps, separators, compressors, valves, and their control units.

GDS Components Library includes more than 600 objects ready to use in LabVIEW front panel.

Plant simulations can work with the real plant data and allows for viewing the simulated scenarios of real events. Use of simulation and read data allow for identifying the opportunities and achieving more efficient and energy saving implementations in operational practices.

Need to remember, although it is a polished nice word and first mentioned in 2013, the mentality of Industry 4.0 is not so new to us. The application of the sensors and data use have been increasing in the last several decades. Thanks to the fast tech advancements and the use of the internet applications, we became able to share and collaborate better with Internet of Things (IoT).

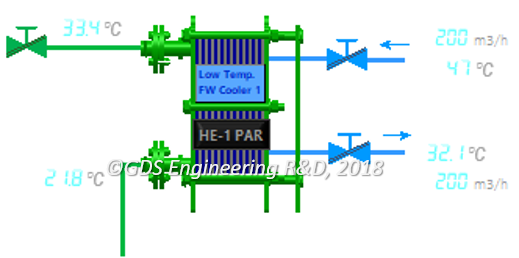

An example to math modeling libraries is shown with Heat Exchangers. The following heat exchanger contains math model of heat exchanger from our library. When heat exchanger is used in a system, the relevant math VI is selected depending on the type and design of heat exchanger from our VI libraries. Above example system uses our math and component models.

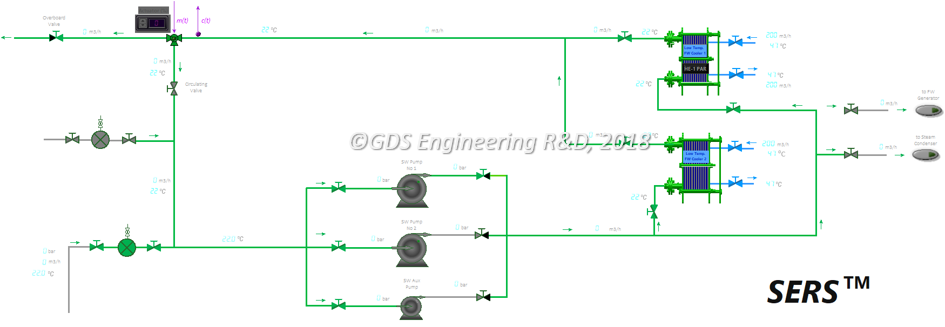

An example of a program developed by our team is shown in below system, which is a cooling system diagram. This system was developed with the approach described above. Using our tools, you can develop fullly interactive piping layout diagrams of your own systems and interface either to your real world systems or to your simulation with a mode switch. In such diagrams engineering values for pressures, temperatures, flow rates are retrieved from your plant data.

The following is a P&ID diagram for a seawater cooling system used onboard a ship. It is a good example for Piping & Ilustration Diagrams (P&ID). With programming, these diagrams become active and live.

- Includes library of programmable Graphical User Interface (GUI) objects for LabVIEW development environment.

- Have over 500 LabVIEW GUI objects: reusable controls, indicators library of valves, pipes, pumps, engines, machines, compressors, sensors and actuators, and other industrial components that you use in your plant processes.

- Accessible within LabVIEW, our libraries contains almost all necessary components to develop a GUI for a plant or process system, as your infrastructure for the Internet of Things (IoT).

- Several application examples (or industries) where our libraries could be used:

- petroleum refinery plants

- electrical generation plants and gen-sets

- robotics and manufacturing plants

- machinery control processes

- systems in ships, airplanes, trains,

- chemical process plants

- food processing plants

- HVAC systems in industrial or building locations

- Crop monitoring systems

- Mining monitoring and control systems

- Sub-sea control and monitoring systems

- Hospital devices monitoring systems

- Filtration and distillation plants

- Pneumatic control systems

- Hydraulic control systems

- and many more…

- This library was developed for use by LabVIEW developers and it is compatible with LabVIEW 2013 or later.

Additionally, we provide several engineering support services for your Industry 4.0 development effort.

- For connecting your plant systems to LabVIEW, we recommend LabVIEW and National Instruments (NI) Data Acquisition and Instrumentation products (www.ni.com). NI provides software and training; however, we can provide engineering services to develop your software to connect your sensor network into your main program.

- We develop twin model of your existing platforms.

- Our experience includes the development of our Ship Engine Room Simulator with

- diesel engines

- steam systems

- electrical systems (electrical generation,consumption, monitoring and control systems)

- compressed air as well as pneumatic control systems

- rudder control (hydraulics)

- distilled water plant

- safety systems, such as CO2 system (Fixed Fire Installation)

- ballast systems

- fuel and lubricating systems

- cooling systems

- pumps, compressors, and separators

- etc.

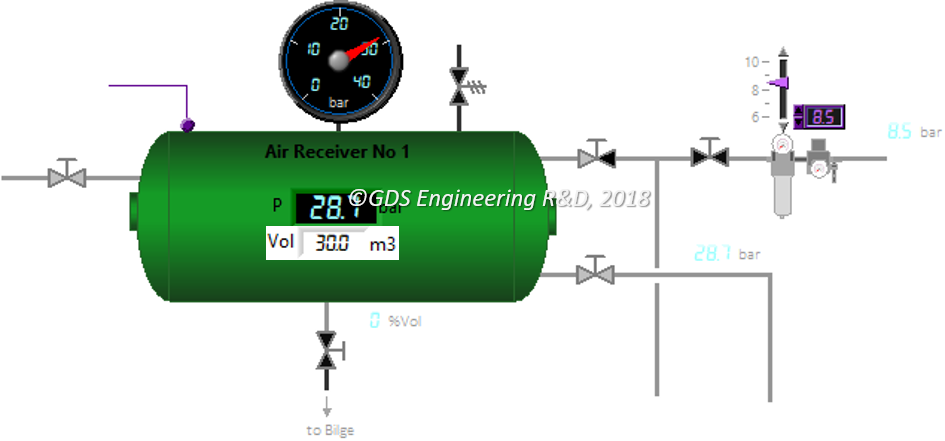

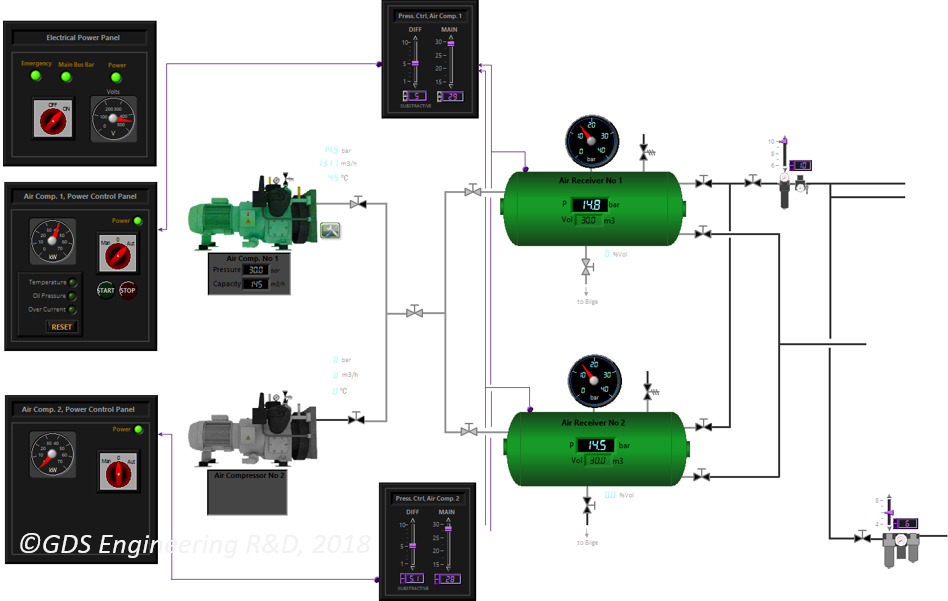

Another example view shown below is from a part of a compressed air system (of a ship). Again, you can use this system to interact to your existing systems, meanwhile you can switch to SIMULATION mode for the analysis of the existing data for various scenarios. It can also well be used for the training of your personnel.

We provide engineering service for

Component Modeling, Mathematical Modeling & Simulation Work Support

(with a Twin-Model Creation of Your Existing Systems and Processes)

Usually, Industrial Monitoring and Control is already in place in most control systems with data. With our LabVIEW tools, you can be upgraded your systems to Industry 4.0. For this, we have simulation GUI tools, including programmable GUI components, such as pipes, valves, tanks, separators, engines and other machinery.

- We can help develop your component modeling and simulation system as either engineering support service to you or we can provide training to your personnel. We generally are experienced to develop 1-GUI-page of system development in several weeks if the layout drawings and the information of the components are available.

- Simulation of your real world systems allow for switching the system work as a simulator for your systems OR you can run your systems with the real-world data. Switching to SIM mode allows you to analyze your systems with or without the plan data. There is a huge potential of using simulator for understanding, monitoring, and controlling your processes with event analysis and many more…

- Please contact us for discussing the details of how much power a Plant Manager may have with a use of a twin model.

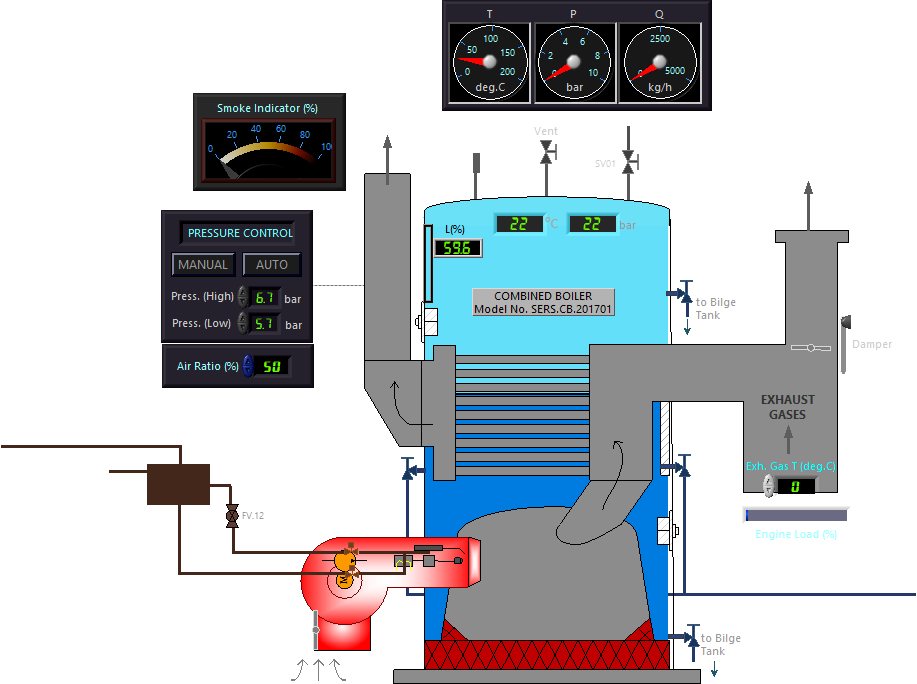

One last example, shown below, is from a Boiler system that includes Boiler system components as well as mathematical models, already incorporated into the systems. Similarly, we have math models for almost all components you may need as well as the mathematical models that drives the processes to simulate the real world systems.

Why did we select National Instruments LabVIEW as the Framework for our Industry 4.0 Tools Development?

Below summary of articles are some examples to read for understanding our answer.

A Practical Guide for Connecting LabVIEW to the Industrial IoT

In this white paper, learn about the three most prevalent communication protocols to connect to cloud-based development platforms for Internet of Things (IoT) applications. You can also find information on some of the most common IoT cloud development platforms such as Amazon Web Services, IBM Bluemix, PTC ThingWorx, and Microsoft Azure. Plus, learn how to connect an NI embedded system, such as CompactRIO, to these cloud platforms through the LabVIEW open graphical development environment.

http://www.ni.com/white-paper/53954/en/

Industry 4.0: From Vision to Implementation

http://www.ni.com/white-paper/53954/en/

Industry 4.0, Smart Factory, and Industrial Internet are some of the terms used to describe the social and technological revolution that promises to change the current industrial landscape. Bosch Software Innovation has been on the forefront of these developments. At this session, get an overview of the status quo and the road ahead based on concrete examples and use cases.

Below is a link to this NI Forums Page, with discussions on the topic:

Factory of Future: Bosch Software Innovation has been on the forefront of these developments. Click on below link to display the BOSCH brochure and read what they do. Page 29 describes how NI LabVIEW is utilized in BOSCH solutions for Data Capturing and Planning.

Factory of the Future

NI announcement of new products to handle IIoT

National Instruments announced a range of new products to handle analogue big data in the Industrial Internet of Things (IIoT) at its 2015 NIWeek conference in Austin, Texas.

National Instruments launches new industrial IoT kit

NI technology can help you extract meaningful insights from your data

With the NI platform, you can connect any sensor or actuator to any “thing” to generate accurate and large amounts of data, but what you do with that data is the foundation of any successful IIoT solution. NI technology can help you extract meaningful insights from your data so you can make better business decisions or perform nanosecond analytics and control at the edge, reduce the overall amount of tests you must run, or get your product to market faster and with confidence.

http://www.ni.com/en-tr/innovations/industrial-internet-of-things.html

Maritime Simulator Products

(SERSTM)

SERSTM is a certified, advanced, and Full Mission engine room simulator that can be used in both laboratory and distributed team environment training.

Click to read more about SERSTM.

SESSTM is a software simulation of all electrical systems in a typical engine room. It can be used as a laboratory software or in-class demonstration software.

Click to read more about SESSTM.

HVTSTM is a software, which can be used in the training of high voltage operations onboard a ship, such as Vacuum Circuit Breaker, Transformer, and high power loading to the main bus.

Click to read more about HVTSTM.

(VPLTM)

VPLTM is software, which supports the laboratory sessions of Physics I and and II experiements, which are mechanical and electrical experiments, respectively.

Click to read more about VPLTM sotware.

References of GDS Simulator Users

&

Solution Partners

in

Maritime Training and Research

|  |  | ||

| ||||

|  | |||

|  |  | ||

|  |  | ||

|