A Group Training Might be a Good Option for your Organization?

- Training can be customized to your organizational needs. In such cases, training could emphasize selected topics in more details with additional discussions and Qs & As.

- Group trainings of 10 or more adds no additional cost.

- Group trainings of 15 or more, discounts will apply.

- Maximum training class size is 20 in order to ensure the efficiency of the training.

About the Training on MIL-STD-810H Testing:

A Hands-on “Online” or “Onsite” Training Class

Led by a live, U.S. based instructor

MIL-STD-810H

Department Of Defence Test Method Standard

Environmental Engineering Considerations and Laboratory Tests

Training Scope and Contents:

- A good understanding of product testing in view of MIL-STD-810G/H and other relevant military standards.

- Overview of Systems Engineering, V&V, and Concepts of Operations (CONOPS) document.

- Establishment of Test Requirements and Test Plans.

- Test Procedures, Scheduling, Implementation, and Test Reports.

- Tests are covered in detail per MIL-STD-810. Altitude, temperature, humidity, shock, vibration, acceleration, salt fog, explosive atmosphere, etc..

- Some tests MIL-STD-810H tests are covered briefly; however, we ensure all questions are answered in each topic.

- Cases studies, sample reports and discussions on issues.

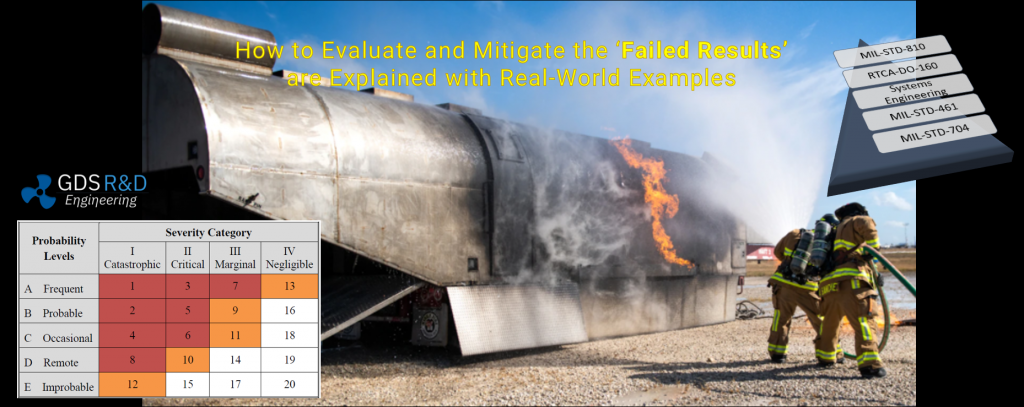

- Design issues and test failure discussions.

- Risk management for test results and acceptance criteria.

- Design Recommendations.

Platform and equipment test examples are provided in each test method presentations and discussions, including:

- Military aircraft platforms (fixed and rotary wing), ground vehicles, and navy ships

- Avionics, electrical and mechanical systems, and structural project applications

- Test tailoring examples to include the selection of tests, parameter levels, and durations

- Concepts of Operations (CONOPS) document and test curve establishment.

- Tailoring and Life Cycle Environmental Profile (LCEP)

Method and Schedule of the Training Class:

- Online training using ZOOM

- Led by a live, U.S. based instructor (Dr Ismail Cicek)

- 2.5 days of training

- 1st Day: 08:00 – 16:00 (Lunch Break between 11:30 and 12:30)

- 2nd Day: 08:00 – 16:00 (Lunch Break between 11:30 and 12:30)

- 3rd Day: 08:00 – 12:00

- Time zone: Central European Time (CET)

- Registration includes all presentations and additional material shared before the class.

- Attendees will receive a Training Certificate.

- Training includes knowledge check quizzes, a competition type fun way or learning.

How to Register:

Send your training/registration requests or specific questions

to our Training Contact Person

@

info@GlobalDynamicSystems.com or aozdemir@tr-test.com.tr

+90 (537) 210-4068 | +90 (312) 923 99 99

About Trainer:

Training is provided by Dr Ismail Cicek with several assistance from personnel experienced in MIL-STD-810 testing.

Dr. Cicek studied PhD in Mechanical Engineering Department at Texas Tech University in Texas, USA. He study included random vibration. He has both industrial and academic experience for over 30 years.

He gained engineering and leadership experience in the United States Department of Defence projects and programs as systems development engineer about 15 years. He led the development of various engineering systems for platforms including C-5, C-17, KC-10, KC-135, and C-130 E/H/J. Dr. Cicek’s experience includes unmanned aerial vehicle development where he utilized the Geographical Information Systems (GIS) and Malfunction Data Recorder Analysis Recorder System (MADARS) development for military transport aircraft.

Dr Cicek worked as the lab chief engineer for five years at the US Air Force Aeromedical Test Lab at WPAFB/OH. He received many important awards at the positions he served, due to the excellent team-work and his detail oriented and energetic personality. These included Terra Health’s Superior Client Award in 2009 and Engineering Excellence Award in 2010 as well as an appreciation letter from the US Air Force Aeronautical Systems Center (ASC), signed by the commander in charge.

Dr Cicek also established a test lab, called Marine Equipment Test Center (METC) and located at Istanbul Technical University, Tuzla Campus, for testing of equipment per military and civilian standards, such as RTCA-DO-160. Providing engineering, consultancy, and training services to many companies and organizations, Dr. Cicek has gained a great insight into the tailoring of standard test methods in accordance with military standards, guides, and handbooks as well as Life Cycle Environmental Profile LCEP) developed for the equipment under test.

Dr. Cicek also completed various product and research projects, funded in the USA, EU, and Turkey. He is currently teaching at Istanbul Technical University Maritime Faculty, Tuzla/Istanbul. He also manages the Marine Equipment Test Center in Tuzla Campus.

This short training on MIL-STD-810H testing class will provide education in the purpose of each test (with emphasis on CONOPS and LCEP documents), the following:

- Equipment required to perform

- Selection of procedures

- Correctly identifying test conditions

- Test durations

- The methodology to correctly apply the specified test environments

Vibration test methods will be covered in detail with fundamental topics, such as sine, random, sine on random, dwell, and sweep testing. The trainer of the class has Ph.D. in mechanical engineering with PhD thesis study on random vibrations and he served in several test laboratories gaining hand on practice on military and aviation standards over the years.

Shock and acceleration testing will be covered using MIL-STD-810 and additional material to cover the methods and selection of tests. Dr. Cicek has developed acceleration test process at US Air Force laboratory for certifying certain products per military standards for in-service use.

More about Training Contents:

MIL-STD-810H, Method 500.6 Low Pressure (Altitude)

MIL-STD-810H, Method 501.7 High Temperature

MIL-STD-810H, Method 502.7 Low Temperature

MIL-STD-810H, Method 503.7 Temperature Shock

MIL-STD-810H, Method 504.3 Contamination by Fluids

MIL-STD-810H, Method 505.7 Solar Radiation (Sunshine)

MIL-STD-810H, Method 506.6 Rain

MIL-STD-810H, Method 507.6 Humidity

MIL-STD-810H, Method 508.8 Fungus

MIL-STD-810H, Method 509.7 Salt Fog

MIL-STD-810H, Method 510.7 Sand and Dust

MIL-STD-810H, Method 511.7 Explosive Atmosphere

MIL-STD-810H, Method 512.6 Immersion

MIL-STD-810H, Method 513.8 Acceleration

MIL-STD-810H, Method 514.8 Vibration

MIL-STD-810H, Method 515.8 Acoustic Noise

MIL-STD-810H, Method 516.8 Shock

MIL-STD-810H, Method 517.3 Pyroshock

MIL-STD-810H, Method 518.2 Acidic Atmosphere

MIL-STD-810H, Method 519.8 Gunfire Shock

MIL-STD-810H, Method 520.5 Combined Environments

MIL-STD-810H, Method 521.4 Icing/Freezing Rain

MIL-STD-810H, Method 522.4 Ballistic Shock

MIL-STD-810H, Method 523.4 Vibro-Acoustic/Temperature

MIL-STD-810H, Method 524.1 Freeze / Thaw

MIL-STD-810H, Method 525.2 Time Waveform Replication

MIL-STD-810H, Method 526.2 Rail Impact

MIL-STD-810H, Method 527.2 Multi-Exciter

MIL-STD-810H, Method 528.1 Mechanical Vibrations of Shipboard Equipment (Type I – Environmental and Type II – Internally Excited)

Relation with RTCA-DO-160 Explained:

- Training will provide some comparison between military tests against the FAA/EASA certification test requirements covered in RTCA-DO-160.

- For example, Fire Flammability will be covered in detail in this training.

- Differences in some test procedures, for example, Altitude, Temperature, Water Proofness / Rain / Immersion, Humidity, Contamination by Fluids, Vibrations, Shock and Crash Accelerations, Icing Freezing, and Salt Fog, will be explained with rationale.

- Demonstrating the differences between DO160 and 810 is a great way of understanding the tailoring process iaw MIL-STD-810H.

Relation with Industrial and Other Military Standards Explained:

- In some cases, MIL-STD-810H tests may not be enough; especially when additional specific material requirements are concerned.

- Training covers a test standards session where examples from other military as well as industrial standards are explained briefly. This session provides an understanding into the rationale for choosing MIL-STD-810 test methods or other military/industrial standards.

- For example, military or DO-60 Salt Fog test versus ASTM corrosion tests are explained with when and why you may need other tests.

- Test plans usually include EMI/EMC test procedures. Training will provide a short session with a general overview of the MIL-STD-461 testing and how to select procedures for your equipment and platform.

Emphasis Given into Tailoring:

- Developing a test plan wrt MIL-STD-810 testing might be confusing and if not it is definitely a time consuming process.

- Training will provide an understanding into why and when Concepts of Operations document is needed and how test requirements are established. This will be covered by both presentations and specific product examples in use in specific platforms.How to develop a Lifecycle Environmental Profile will be given by examples.In test method, discussion will cover “what items” and “how” they will be tailored.

Who Should Attend?

- Program Managers to understand the test scheduling and planning. Also, it is important for them to establish a “test review team”.

- Technical Leads and Requirements Managers to understand how to write correct test requirements

- Test personnel to learn how to implement the tests

- Design teams to learn what to consider in their design to pass the testsPersonnel responsible for test plans

- Decision makers to understand the strategy when choosing certain test procedures in their product life cycle planning for target platforms and for marketing.

- All candidates of Systems Engineering professionals.

We have provided Systems Engineering Training courses to more than 50 Organizations and over 200 individual trainees so far.

Read More about this training:

MIL-STD-810H Training Contents