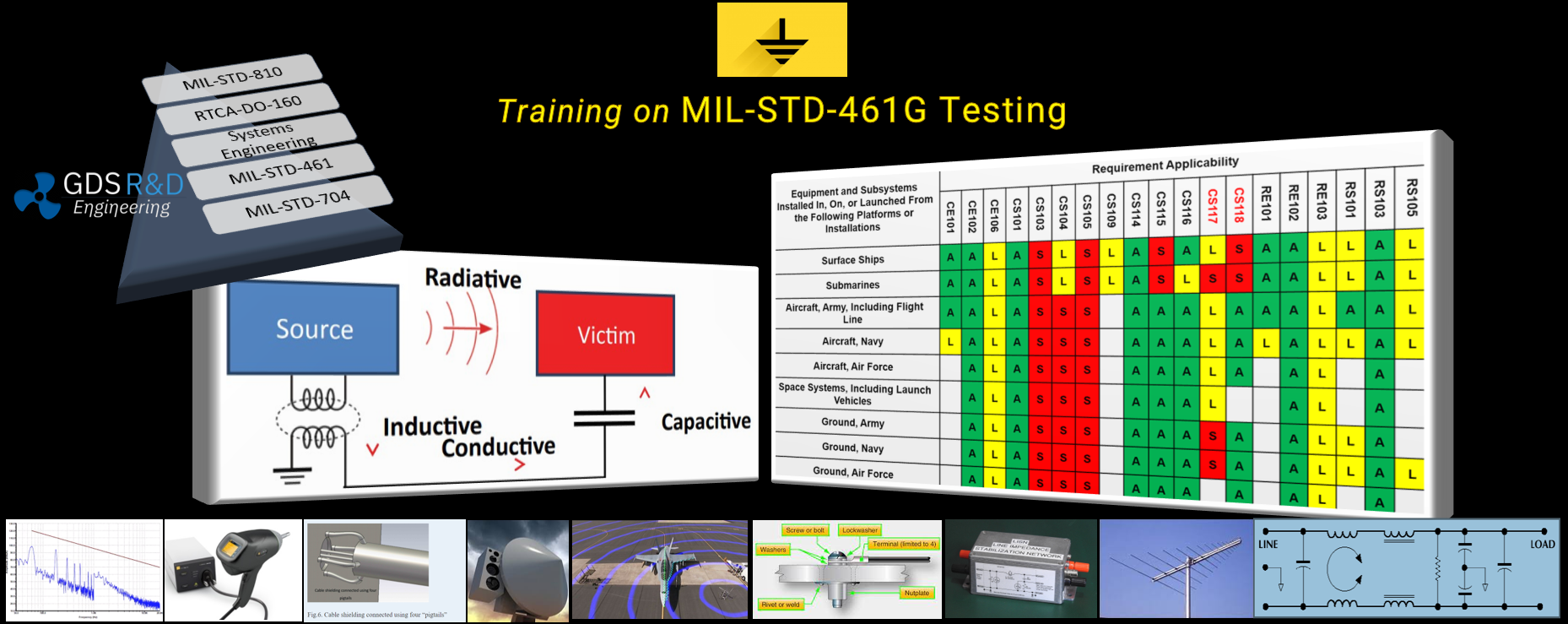

MIL-STD-461G EMI/EMC, ONLINE TRAINING

461 TRAINING provides you the information, background, terminology, protocols, test methods, and requirements necessary to understand, design, and implement MIL-STD-461.

About MIL-STD-461G Test Standard

This Standard contains materiel acquisition program planning and engineering direction for considering the influences that environmental stresses have on materiel throughout all phases of its service life. It is important to note that this document does not impose design or test specifications. Rather, it describes the environmental tailoring process that results in realistic materiel designs and test methods based on materiel system performance requirements.

MIL-STD-461 is a United States Military Standard developed to define how equipment should be tested in regards to their electromagnetic compatibility. The most recent version of MIL-STD-461 is the MIL-STD-461G, which is the result of several corrections over years. However, there are still many military contracts mandating the compliance to MIL-STD-461F.

About MIL-STD-461G Compliance

MIL-STD-461 is basically is a military standard and thus not mandated outside the US military, but several civilian agencies and corporates also adopt this standard as it provides comprehensive procedures and guidelines in the field of electromagnetic. Plus, in order to sell their products and services to military, companies establish their anechoic chamber to conform to MIL-STD-461 in electromagnetic compatibility test labs. In other words, civilian organizations use MIL-STD-461 for two reasons:

Applicable for Enclosures and Electrical Equipment

This standard regulates interface and the relevant verification criteria in order to monitor the emission of an electromagnetic interference (EMI) and its liability associated with electronic, electrical, and electromechanical tools and subsystems created or assembled to be employed in any missions or activities related to the Department of Defense (DoD). The stated equipment and subsystems could be applied individually or as an essential component of other subsystems or systems. MIL-STD-461 is mostly suitable for the elements with the following qualities:

- Electronic enclosures that are no larger than an equipment rack

- Electrical interconnections that are distinct wiring harnesses between enclosures

- Electrical power input coming from prime power sources

MIL-STD-461 should not, however, be used in the elements such as modules positioned within electronic enclosures or the whole platforms. Though, the rationale of the standard could be helpful to use as a foundation for developing appropriate characteristics for those applications.

MIL-STD-461G EMI/EMC Training Scope and Contents (2.5 days)

2.5 days of training covers the following topics

- EMI/EMC Training, Opening Session

- General understanding of EMI and EMC.

- Introductory Design Considerations: Grounding, Bonding, and Shielding.

- MIL-STD-461G Standard General Overview

- Introduction & History

- MIL-STD-461: General overview, definitions, nomenclature, purposes, language, and scope

- MIL-STD-461 Contents Overview

- General and detailed requirements

- Selection of test methods and procedures based on the platform and equipment type

- MIL-STD-461G – CE Tests (Part I)

- Conducted Emissions Test Methods CE101, CE102, CE106

- Example Test Results and Report Reviews

- Q&As

- MIL-STD-461-G – CE Tests (Part II)

- Conducted Emissions Test Methods CE101, CE102, CE106

- Example Test Results and Report Reviews

- Q&As

- MIL STD 461G – CS Tests (Part I)

- Conducted Susceptibility Test Methods CS101, CS103, CS104, CS105, CS109

- Example Test Results and Report Reviews

- Q&As

- MIL STD 461G – CS Tests (Part II)

- Conducted Susceptibility Test Methods CS114, CS115, CS116, CS 117, CS 118

- Example Test Results and Report Reviews

- Q&As

- Product Development and Certification Process

- US DOD Systems Engineering V&V Processes, R&D Project vs. End Product

- Certification Process (MIL-STD-461, MIL-STD-464, MIL-HDBK 516, US DOD )

- USAF and US Army EMI/EMC Test and Certification Process

- FAA/EASA Part 21 ve Certification Process

- Documentation, Test Plans, and Test Reports

- Test Plan Examples

- Test Results and Risk Assessment

- Test Reports

- US DOD Data Items (DI) Forms and Data Item Descriptions (DID), governmental and non-governmental documentation

- MIL-STD-464 Standard

- MIL-STD-461 vs MIL-STD-464

- EMI/EMC Platform Level Requirements Review

- MIL-STD-464 Guides: Requirements Rationale and Lessons Learnt Items

- MIL-STD-461G RS Tests

- Radiated Susceptibility Test Methods RS101, RS103, RS105

- Example Test Results and Report Reviews

- Q&As

- MIL-STD-461G RE Tests

- Radiated Emissions Test Methods RE101, RE102, RE103

- Example Test Results and Report Reviews

- Q&As

- EMI/EMC & Equipment Design

- EMI/EMC and Equipment Design

- EMI/EMC Analysis Software Programs and Application Examples

- EMI/EMC Analysis Test Programs

- Additional Tests (RTCA-DO-160)

- Power Input, RTCA-DO-160G Section 16

- Magnetic Effect, RTCA-DO-160G Section 15

- Lightning Direct Effects, RTCA-DO-160G Section 23

- Other Relevant Test Standards, Brief Summary

- MIL-STD-464D Electromgnetic Environmental Effects, Requirements for Systems

- MIL-STD-704F Aircraft Electric Power Characteristics

- MIL-STD-1275E Interface Standard, Characteristics of 28 Volt DC Input Power to Utilization Equipment in Military Vehicles

- MIL-STD-1399 Interface Standard, Section 300, Part 1 Low Voltage Electric Power, Alternating Current

- MIL-STD-1399 Interface Standard, Section 300, Part 2 Medium Voltage Electric Power, Alternating Current

Note:

All MIL-STD-461G test sections are discussed and explained in detail, including

- All MIL-STD-461G test sections are discussed and explained in detail, including

- The Purpose of the Test

- Test Configurations and General Requirements

- Test Requirements and Procedures

- EMI Test Chamber

- Test Setup: Test Setup (Tabletop) / Test Setup (Free Standing)

- Measurement Tolerances

- Interpretation of the Test Results and Example Test Report Reviews

- Issues that might be observed with recommendations (based on design experience).

Who Should Attend?

- Test personnel to learn how to implement the tests

- Design teams to learn what to consider in their design to pass the tests

- Technical Leads and Requirements Managers to understand how to write correct test requirements

- Personnel responsible for test plans

- Program Managers to understand the test scheduling and planning. Also, it is important for them to establish a “test review team”.

- Decision makers to understand the strategy when choosing certain test procedures in their product life cycle planning for target platforms and for marketing.

Training Schedule and Execution Method

- Training Type: International / Online

- Satus: OPEN

- Course Material: English

- Comm. Language: English

- Online training using ZOOM.

- Led by a live, U.S. based instructor (Dr Ismail Cicek)

- 2.5 days of training

- 1st Day: 08:00 – 16:30 (Lunch Break between 12:00 and 13:00)

- 2nd Day: 08:00 – 16:30 (Lunch Break between 12:00 and 13:00)

- 3rd Day: 08:00 – 12:30

- Time zone: Central European Summer Time (CEST) / UTC+2

- Material: Registration includes all presentations and additional material (English) shared before the class.

- Attandance: The link for online class is distributed to registered trainees one day before the training date.

- Attendees will receive a Training Certificate.

- Training includes knowledge check quizzes, a competition type fun way or learning.

About the Instructors

The main instructor of the training is Dr Ismail Cicek. An Avionics Chief Engineer (EE) who is also a Certified Verification Engineer (FAA/EASA) also assists the trainings. Our experienced test personnel also becomes avialable for demonstrations and discussions.

A Certified Verification Engineer (CVE) iaw FAA/EASA and with 18 years of experience. He has worked as the avionics systems chief engineer in product development of avionics systems. He is also experienced in the product testing per environmental and EMI/EMC standards and FAA/EASA certification processes.

Our experienced personnel also support our training programs. They are actively participating in the environmental testing of products.

Dr. Ismail Cicek studied PhD in Mechanical Engineering Department at Texas Tech University in Texas, USA. He study included random vibration. He has both industrial and academic experience for over 30 years.

He gained engineering and leadership experience by working in the United States Department of Defence projects and programs as systems development engineer for 15 years. He led the development of various engineering systems for platforms including C-5, C-17, KC-10, KC-135, and C-130 E/H/J. Dr. Cicek’s experience includes unmanned aerial vehicle development where he utilized the Geographical Information Systems (GIS) and Malfunction Data Recorder Analysis Recorder System (MADARS) development for military transport aircraft.

Dr Cicek worked as the lab chief engineer for five years at the US Air Force Aeromedical Test Lab at WPAFB, OH. He received many important awards at the positions he served, due to the excellent team-work and his detail oriented and energetic personality. These included Terra Health’s Superior Client Award in 2009 and Engineering Excellence Award in 2010 as well as an appreciation letter from the US Air Force Aeronautical Systems Center (ASC), signed by the commander in charge.

Dr Cicek also established a test lab, called Marine Equipment Test Center (METC) and located at Istanbul Technical University, Tuzla Campus, for testing of equipment per military and civilian standards, such as RTCA-DO-160. Providing engineering, consultancy, and training services to many companies and organizations, Dr. Cicek has gained a great insight into the tailoring of standard test methods in accordance with military standards, guides, and handbooks as well as Life Cycle Environmental Profile LCEP) developed for the equipment under test.

Dr. Cicek also completed various product and research projects, funded in the USA, EU, and Turkey. He is currently teaching at Istanbul Technical University Maritime Faculty, Tuzla/Istanbul. He is the founding manager of the METC in Tuzla Campus of ITU. Meanwhile, he provided engineering services, consultancies, and training to many organizations for product development, engineering research studies such a algorith development, test requirements development, and test plans and executions.

Dr Cicek worked as the Principle Investigator and became a Subject Matter Expert (SME) at the US Air Force Aeromedical Test Lab (WPAFB/OH) for certifying the products to the US Air Force Platform Requirements. He also developed Joint Enroute Care Equipment Test Standard (JECETS) in close work with US Army Test Lab engineers and managers.

Read DAU Paper: “A New Process for the Acceleration Test and Evaluation of Aeromedical Equipment for U.S. Air Force Safe-To-Fly Certification”. Click to display this report.

Connect with Dr Ismail Cicek: Linkedin Page

Click here to read more about Dr Cicek’s professional studies.

GDS Systems Engineering V&V Training Courses

Event Calendar

We announce upcoming training on these pages. Due to COVID-19 pandemic situation, we offer only ONLINE training courses for the time being. Please communicate with us if you need a group training, which could be scheduled based on your plans and schedules.

Select the best training from below list that fits to your training needs.

Training Registration Request Form

Please fill out the following form for asking your question or with a registration request. Thank you for your interest in our training programs.

GLOBAL DYNAMIC SYSTEMS (GDS)

TRAINING COURSES

Worldwide, Online, for ‘Groups’ or ‘Individuals’

Training on

MIL-STD-810H

ENVIRONMENTAL TESTING

Training on

EMI/EMC Testing

(per RTCA-DO-160 & MIL-STD-461)

Training on

Vibration and Shock

Testing

Training on

Systems Engineering

(DoD/FAA/NASA/EASA)

Training on

RTCA-DO-160G

ENVIRONMENTAL TESTING

Training on

MIL-STD-461G EMI/EMC Testing

(incl. MIL-STD-464)

Training on

Requirements Management

(FAA/EASA/US DoD/NASA)

Training on

MIL-STD-704F

Aircraft Electrical Interface

OUR REFERENCES

We have provided training and test consultancy services to more than 100 companies and organizations and over 500 individual trainees so far.

|  |  |  |  |

|  |  |  |  |

|  |  |  |  |

|  |  |  |  |

|  |  |  |  |

|  |  |  |  |

|  |  |  |  |

|  |  |  |  |

|  |  |  | |

|  |  |  |  |