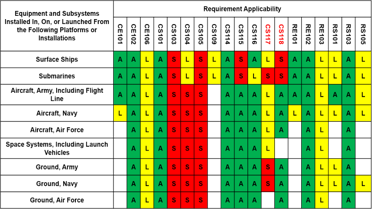

MIL-STD-810H, US DOD Test Standard, starts with an important phrase at the beginning paragraph of each of the 28 test methods: “Tailoring is Essential.” It is therefore crucial to understand what this means and how to tailor the test methods for specific equipment, considering the platform, mission, and environmental requirements.

GDS Engineering R&D provides MIL-STD-810H training online or onsite. Performing operations in various parts of the world, we have been providing this course to the defence industry strategists, leaders, program managers, projects managers, designers, and test engineers for more than 10 years. With long years of background in test projects in the USA and Turkey, Dr. Cicek, the main lecturer of this training, explains the tailoring concepts with specific examples.

This course provides with information and knowledge of experience on how to develop Concepts of Operations (CONOPS) document and Lice Cycle Environmental Profile (LCEP) to derive operational therefore test requirements for the Equipment Under Test (EUT). Understading the tailoring part of MIL-STD-810H is probably the most important aspect of this test standard training, due to the following reasons:

- Developing a test plan for MIL-STD-810H equipment testing might be a confusing and time consuming process.

- Training will provide an understanding into why and when CONOPS document is needed and how test requirements are established along with Mission and Environmental profiles of the EUT. These are all covered by both presentations and specific product examples through discussions during the training sessions.

- In test method discussions, the instructor discuss “what items” (i.e. test levels) and “how” they will be tailored with specific examples.

Test methods, i.e. temperature, humidity, temperature shock, require mission and environmental profiles are established for successfully determining the test levels, durations, and criteria for pass or fail.

Consider the following for tailoring

A Generalized Task Statement for Tailoring: Condider the environmental effects. An example list is provided with a list below. Develop exposure curves considering exposure scenarios. For this, use/develop CONOPS document and generate a Life Cycle Environmental Profile (LCEP).

- Environmental effects (temperature, humidity, icing, etc.) to the equipment in different operational modes: i.e. transportation, operation, and stand-by. Condider these effects with scenarious and develop exposure curves.

- Equipment vulnarabilities under the environmental/operational conditions.

- Effects caused by the platform operations (vibrations, shock, etc.)

- The effect due to the platform environment; various conditions in the section the equipment will be operating. For example, the equipment might be exposed to fluid contamination in the section where it will be installed.

- Equipment’s effect to the environment and systems (EMI, vibrations, fluid contamination, fire and flammability, etc.)

- Consider risks of operational breakdowns with “what if” scenarios.

GDS MIL-STD-810H Training: Scope and Contents

- A good understanding of product testing in view of MIL-STD-810G/H and other relevant military standards.

- Overview of Systems Engineering, V&V, and Concepts of Operations (CONOPS) document.

- Establishment of Test Requirements and Test Plans.

- Test Procedures, Scheduling, Implementation, and Test Reports.

- Tests are covered in detail per MIL-STD-810. Altitude, temperature, humidity, shock, vibration, acceleration, salt fog, explosive atmosphere, etc..

- Some of the MIL-STD-810H test methods are covered briefly; however, we ensure all questions are answered for each test method.

- Cases studies, sample reports and discussions on issues.

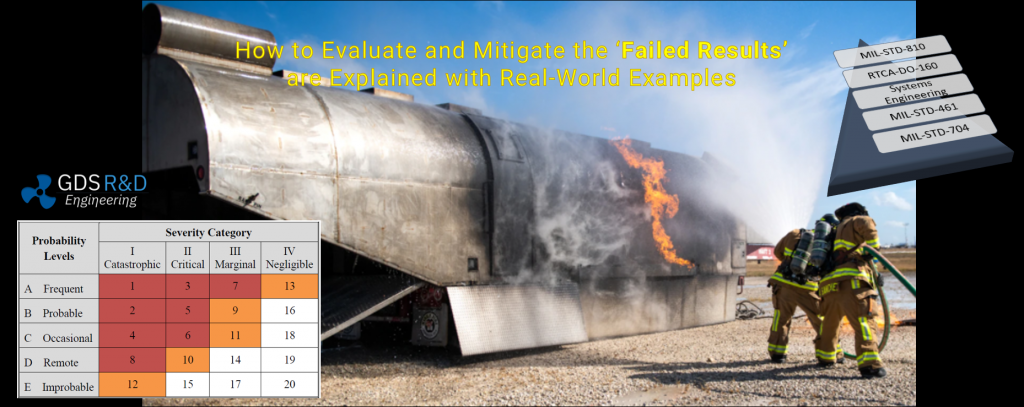

- Design issues and test failure discussions.

- Risk management for test results and acceptance criteria.

- Design Recommendations.

Read more information in our MIL-STD-810H Training pages.

GDS Systems Engineering V&V Training Courses

Event Calendar

We announce upcoming training on these pages. Due to COVID-19 pandemic situation, we offer only ONLINE training courses for the time being. Please communicate with us if you need a group training, which could be scheduled based on your plans and schedules.